Parts and components used in industry products have become increasingly precise while its top-notch surface quality has never been compromised. These requirements are not an option but to be embraced by manufacturers who want to get their names recognized in the tough competition environment.

Why Sumitomo Develop This Product?

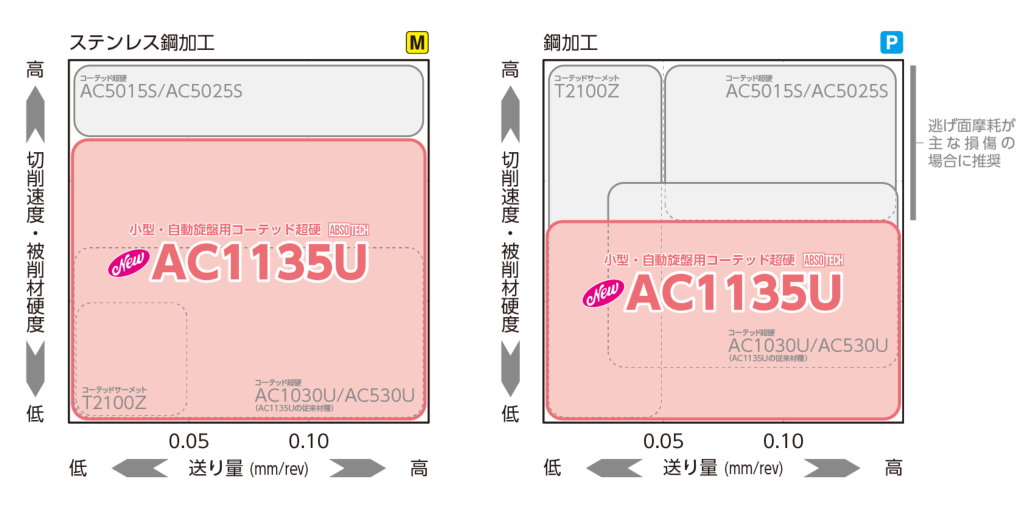

As mentioned in the news release recently, Sumitomo Electric Hardmetal (Thailand) Ltd., claims that in recent years, components, especially in the automotive and semiconductor manufacturing equipment fields, have become increasingly precise, and the demands for small lathe/autolathe tools used for precision parts machining is increasing year by year. The use of stainless-steel parts with excellent durability and thermal resistance is increased as well, while machining of highly corrosion-resistant materials such as SUS316L tend to shorten tool life, leading to increased tool costs and replacement frequency.

Coated Carbide Grade AC1135U for Small Lathes/Autolathes

The new AC1135U grade is engineered for stainless steel machining with improved machining stability, longer tool life and higher machined surface quality. AC1135U, utilizing a proprietary coating technology, delivers excellent adhesion resistance and wears resistance in small lathe and autolathe machining, significantly reduces tool replacement frequency and lowering machining costs.

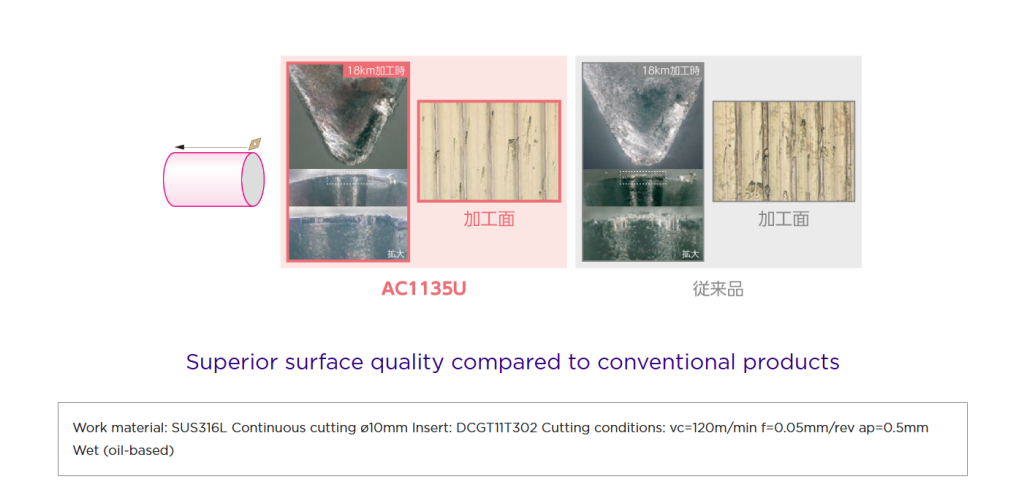

Superior Surface Quality

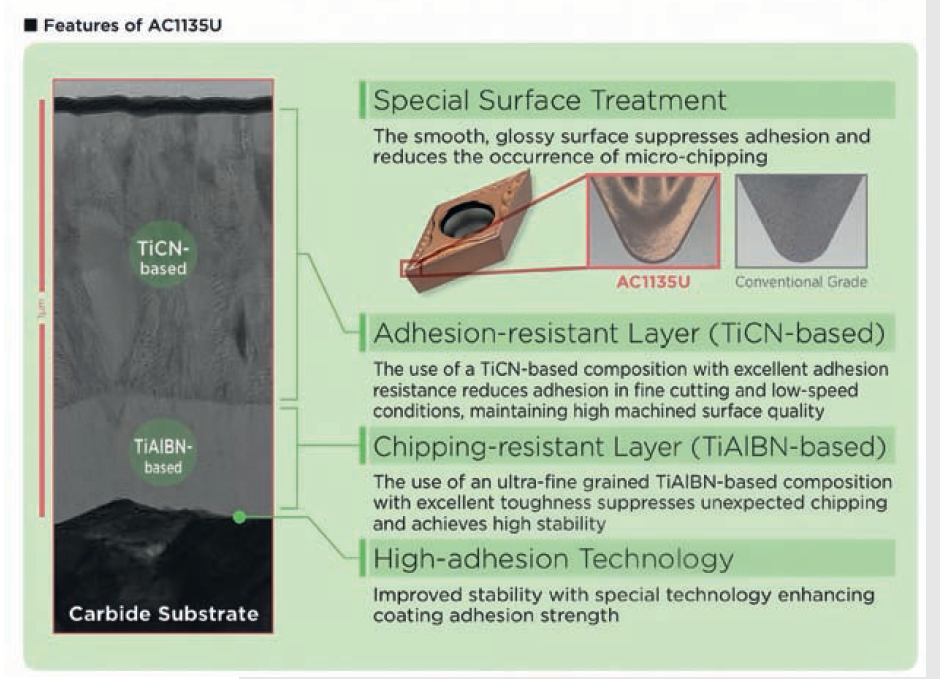

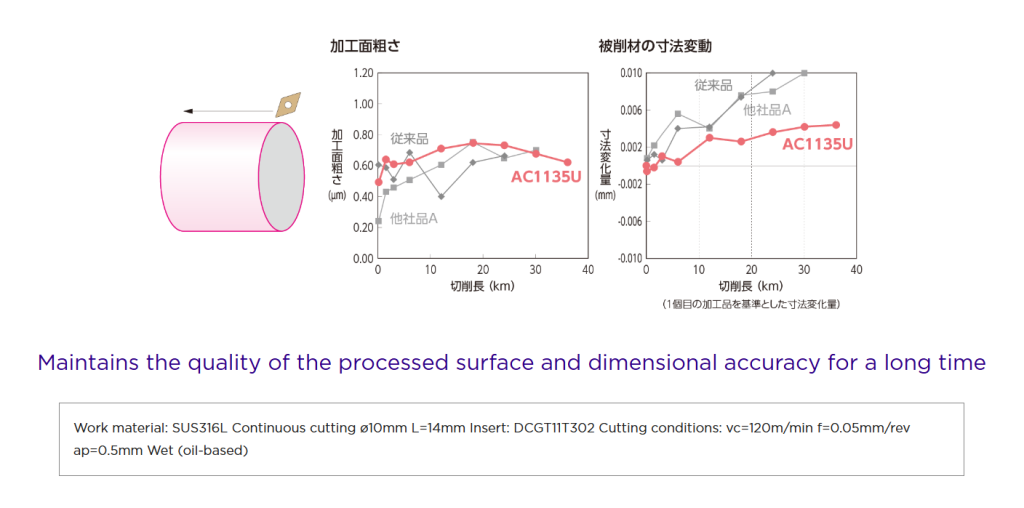

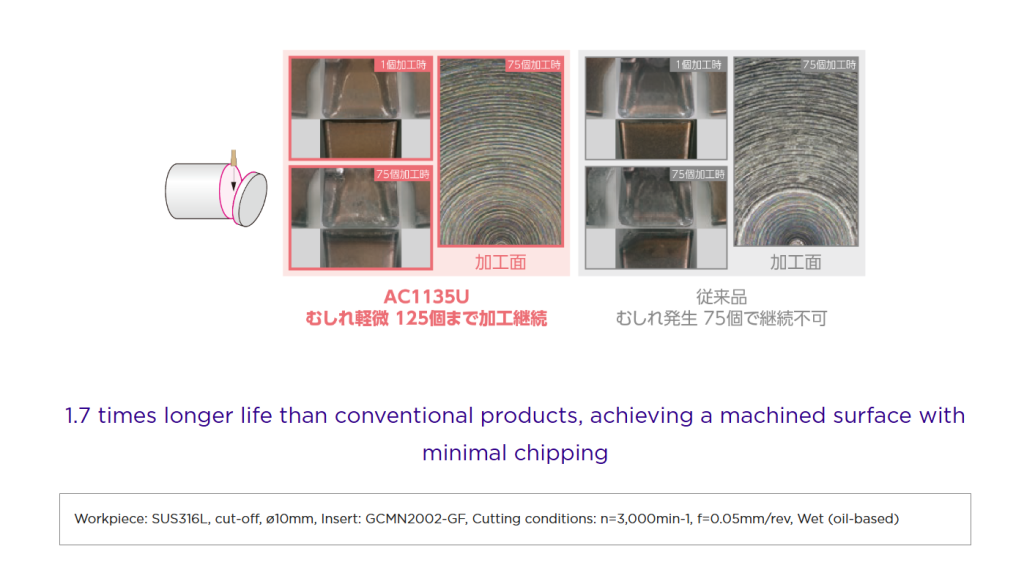

The AC1135U utilizes the company’s proprietary PVD coating technology ABSOTECH™ which combines high strength and high hardness, along with adhesion resistance, to realize high machining stability and longer tool life. A special surface treatment used here for the first time, suppresses adhesion to the cutting edge, a common issue when machining stainless steel, allowing the smooth, glossy surface suppresses adhesion and reduces the occurrence of micro-chipping to achieve a significantly higher machined surface quality as compared to conventional grades.

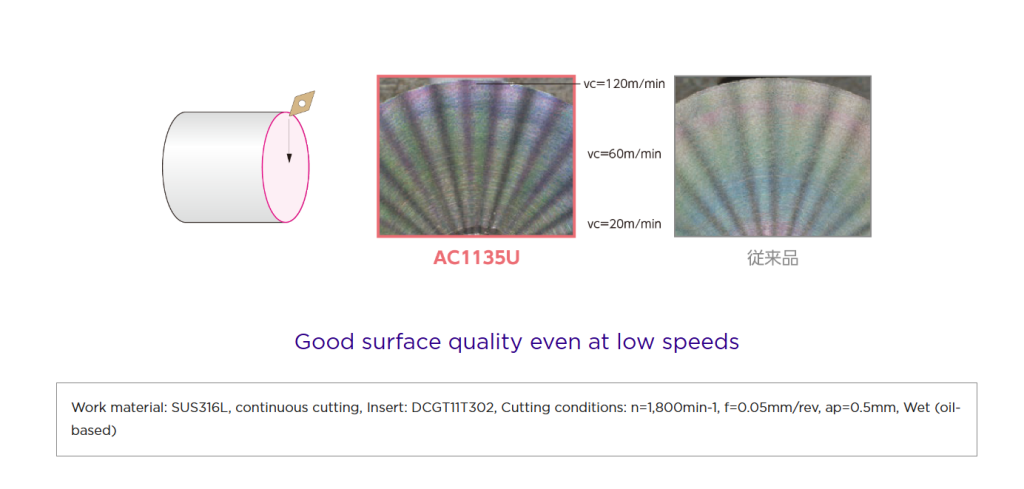

Furthermore, the finished parts feature excellent machined surface quality even at low speeds that normal in small lathe machining. Machined surface quality in external grooving and in cut-off machining (stainless steel) is superior to conventional grades.

The ABSOTECH™ also allows for a much longer tool life and significantly reduces the frequency of tool replacements. Less frequent tool changes mean less machine downtime for setups and replacements. This increases overall production efficiency and throughput, which translates into lower manufacturing costs and increased the profits.

High Machining Stability & Cost Efficiency

The combination of the coating and a tough carbide substrate ensures excellent stability during cutting operations. This is especially crucial for the precise demands of small lathes and automatic lathes (Swiss-type machines) where components are increasingly precise, such as those used in automotive and semiconductor equipment fields. Besides, coated tools can often operate at higher cutting speeds and feed rates compared to uncoated tools. This increases productivity without compromising tool integrity, making the overall operation more cost-effective. By extending tool life, increasing cutting speeds, and improving machining stability, the AC1135U grade lowers overall machining costs and increases production efficiency.

Surface quality achieved by edge processing (stainless steel)

Surface quality achieved by external machining (stainless steel)

Stable performance due to external diameter processing (stainless steel)

Surface quality achieved by cutting off (stainless steel)

Target Applications

The Sumitomo AC1135U grade coated carbide is designed for high-accuracy, high-efficiency machining of small components, primarily targeting stainless steel applications.

The grade is specifically developed to optimized for machining various stainless steels, including highly corrosion-resistant materials like SUS316L, where it addresses issues like built-up edge and short tool life. The resulting components are often used in demanding fields that require high precision of the automotive industry and semiconductor manufacturing equipment.

Summary

In essence, the AC1135U grade addresses the specific challenges of small parts machining, such as reducing heat, adhesion, and maintaining precision, resulting in a more reliable and efficient manufacturing process. The AC1135U lineup consists of 155 different catalog numbers (Cat. Nos.) and insert lineup covers a wide range of standard turning inserts. The new AC1135U is available for sale in Thailand through authorized Sumitomo distributors, most notably Sumipol Corporation Limited.

Learn more The New AC1135U << Click here

Contact us if interested Sumipol Corporation Limited << Click here

Article by: MEGATech & Sumipol Corporation Limited << Click here