Amid the global transition toward electric vehicles, automation, and smart technologies, Japan remains a key driving force in the evolution of the automotive industry. Backed by decades of engineering expertise, an efficient supply chain, and a strong commitment to sustainable innovation-ranging from battery and fuel-cell technologies to autonomous and driverless systems as well as smart manufacturing-Japan continues to set new benchmarks for performance and safety.

On this occasion, MEGA Tech invites you to explore the perspectives of leading Japanese manufacturers of machinery, metrology, and cutting tools, to gain deeper insights into automotive industry trends and the emerging opportunities for manufacturers.

Mr. Isao Ogasawara – President of JTEKT Machinery (Thailand) Co., Ltd.

Mr. Shunji Uchida – Managing Director of Mitutoyo (Thailand) Co., Ltd.

Mr. Kamihito (Jin) Kakegawa – Managing Director of Sumitomo Electric Hardmetal (Thailand) Ltd.

Mr. Hiromiki Goto – Director – Sales Division of Sodick (Thailand) Co., Ltd.

“After-sales Excellence” Ensuring Lasting Performance with Trusted Japanese Quality

Mr. Isao Ogasawara

President of JTEKT Machinery (Thailand) Co., Ltd.

Japanese Automotive Innovation: Leading the World into the Future with Sustainable Technology

Japanese automakers are entering a new era of innovation under the CASE framework – Connected, Autonomous, Shared, and Electric – reflecting the key trends shaping the global automotive industry. From an environmental perspective, leading manufacturers are advancing technologies through a Multi-Pathway Strategy, aiming for carbon neutrality and clean energy. They offer a wide range of options, including Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Fuel Cell Electric Vehicles (FCEVs), to meet diverse market demands and varying levels of infrastructure readiness across countries.

Japanʼs strength lies in its expertise in energy-efficient engines and global leadership in hybrid technology. While advancements in battery technology have alleviated concerns over driving range and charging convenience, challenges remain, particularly regarding the development of adequate charging infrastructure in many regions. At the same time, hybrid vehicles are being reevaluated as cost-effective and practical mobility solutions. Global political factors, such as the rise of protectionist trade policies, have further complicated the task of steering the automotive industry solely based on environmental considerations.

As autonomous driving technology matures, electric vehicles are expected to become the backbone of public transportation, buses, and shared mobility services, helping to reduce travel costs and transform the global transportation landscape sustainably.

JTEKT G3 SERIES: High-Precision Grinding Innovation Elevating Manufacturing Efficiency for the Future of EV

Automotive manufacturers around the world are advancing component production through next-generation manufacturing technologies, emphasizing the use of innovative materials and advanced structures. The goal is to achieve maximum production efficiency while accommodating small-batch, multi-model manufacturing – all in alignment with global trends toward sustainability and environmental responsibility. JTEKT stands alongside its customers at every stage of production, providing high-precision grinding machines and high-rigidity machining centers designed to deliver superior quality, accuracy, and productivity.

Renowned for its excellence in the production of engine components and motor shafts, JTEKTʼs grinding machines have earned global recognition. The company is confident that these strengths will play a vital role in expanding its market share within the HEV and BEV segments in the near future. Among JTEKTʼs latest innovations is the G3 SERIES, a new generation of cylindrical CNC grinding machines. Compact in size yet powerful in performance, the G3 SERIES is ideally suited for small workpieces and mass-production applications, with growing demand and strong sales across the ASEAN region.

The key highlight of this model is its STAT BEARING system integrated into the wheel spindle, a proprietary technology developed by JTEKT. By combining both hydrostatic and hydrodynamic pressure principles, the system delivers exceptional machining accuracy, outstanding operational stability, and a significantly extended service life. In addition, the dual-center workholding mechanism enables seamless compatibility with automatic loading systems, including robotic handling. This enhances production automation, improves process efficiency, and contributes to substantial reductions in manufacturing costs.

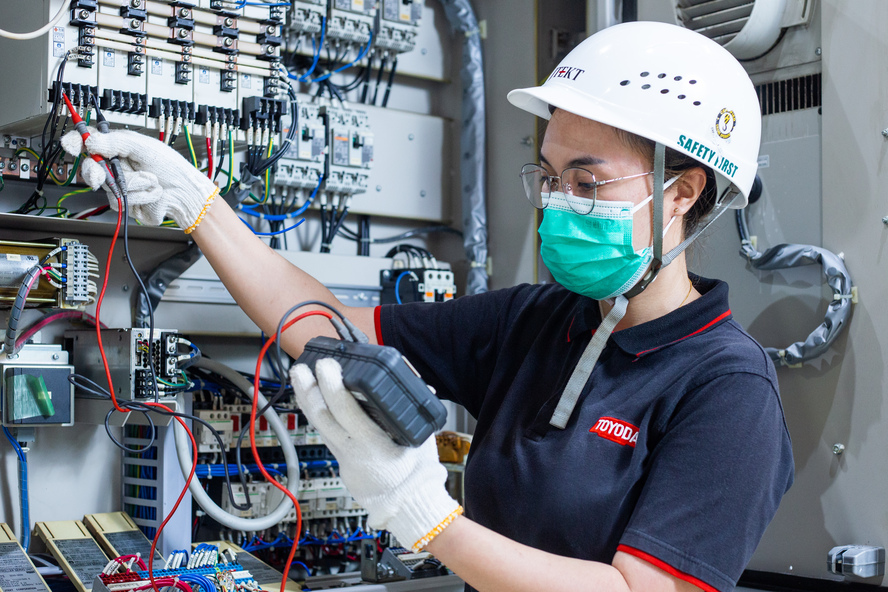

JTEKT Enhances Japanese-Standard Overhaul Services to Extend Lifespan and Restore Performance of Customer Machines in ASEAN

Machinery is one of the most valuable assets in any manufacturing facility – designed for long-term use and requiring continuous care to maintain its precision, performance, and return on investment. Building customer confidence, therefore, depends not only on the quality of the machine at the time of delivery but also on a reliable and sustainable after-sales strategy that ensures lasting support throughout the productʼs life cycle. With this philosophy, JTEKT has developed a comprehensive “Total Support Service”, designed to meet every customerʼs need at every stage – from installation and inspection to maintenance and long-term performance enhancement.

In the ASEAN region, many customers continue to operate durable, long-serving machines that remain vital to their production lines. To keep these machines performing at peak efficiency, JTEKT established an Overhaul Service Center in Thailand, serving as a regional hub for machine restoration and performance renewal. The overhaul process strictly follows Japanese factory standards, covering disassembly, inspection, cleaning, polishing, replacement of mechanical and electrical components, during actual operation ensuring that each machine regains the precision and efficiency of a new unit.

Beyond overhaul services, JTEKT also provides maintenance solutions for both JTEKT and other machine tool brands, offering reliable support to all customers. Its team of skilled service engineers, trained to Japanese standards, is fully equipped to diagnose and resolve technical issues swiftly, minimizing downtime and helping factories resume production with minimal disruption. With world-class expertise and a deep commitment to quality service, JTEKT strives to be a trusted long-term partner for the manufacturing industry. The companyʼs holistic approach to machine care helps customers maintain stable production, maximize efficiency, and extend the lifespan of their equipment. More than just technical support, JTEKTʼs dedication reflects its core philosophy – to grow together with customers sustainably, empowering industrial progress at every stage of development.

Furthermore, JTEKT offers maintenance and repair services not only for JTEKT machines but also for other brands. With a team of skilled professionals, the company provides prompt and reliable support to restore machines to optimal condition and extend their service life. This ensures that customers can operate with confidence, achieving maximum productivity and long-term operational efficiency.

“Beyond Measurement” Mitutoyo Ensures Precision and Reliability with World-Class After-Sales Support

Mr. Shunji Uchida

Managing Director of Mitutoyo (Thailand) Co., Ltd.

Japanese Automotive Innovation: Leading the World into the Future with Sustainable Technology

In the future of Japanʼs automotive industry, electrification is set to become the primary direction. The Japanese government has set a target for 100% of new car sales to be electric vehicles (EVs) by 2035, prompting major manufacturers such as Toyota, Honda, and Nissan to accelerate the development of BEVs (Battery Electric Vehicles) and FCVs (Fuel Cell Vehicles).

BEVs produce zero carbon dioxide emissions during operation, and when paired with renewable energy sources, can achieve true “zero emissions” However, the limited charging infrastructure outside major urban areas and challenges in ensuring stable electricity supply mean that HEVs (Hybrid Electric Vehicles) and PHEVs (Plug-in Hybrid Electric Vehicles), which combine internal combustion engines with electric power, will continue to play a dominant role in long-distance travel in the near term.

In the long term, BEVs hold the greatest potential, though challenges remain regarding environmental impacts from raw material sourcing and recycling of conventional lithium-ion batteries. The development of all-solid-state batteries, expected to enter practical use around 2027, will improve driving range, shorten charging times, extend battery life, and reduce environmental impact. The transition to renewable energy is also crucial, as many countries still rely on fossil fuels and nuclear power. BEVs, therefore, are not merely “environmentally friendly vehicles” but represent the starting point for transformative changes in energy systems, industry structures, and society at large. In the coming decade, technological innovation, supportive policies, and market adaptability will be key determinants of success. Ultimately, the widespread adoption of BEVs will mark a significant step toward realizing a truly “Sustainable Mobility Society.”

MiSTAR 555: High-Precision CMMs for Fast, Flexible and and Reliable EV Production

Key EV components such as battery cases, motor parts, and inverters require exceptionally high precision. The MiSTAR 555 is designed to meet these demands, allowing immediate measurement of workpieces directly on the shopfloor without transferring them to a metrology room. Equipped with a real-time temperature compensation function, it maintains high measurement accuracy even for workpieces that are still warm after manufacturing.

With high-speed movement and acceleration capabilities, the MiSTAR 555 can easily integrate with various machines and robots, supporting automated and modular production. It operates effectively within a temperature range of 10-40°C and can be installed in limited spaces without the need for compressed air, reducing both infrastructure complexity and costs.

Environmentally, the MiSTAR 555 is engineered for energy efficiency, lowering power consumption and minimizing maintenance requirements. Equipped with an ABSOLUTE Scale designed for harsh environments, it maintains measurement accuracy even in conditions with oil mist and debris. Advanced functions, including condition monitoring and preventive maintenance, contribute to improved equipment utilization and lower operating expenses.

The primary value for customers lies in the assurance of precision and traceability in highly stringent production environments. The MiSTAR 555 enables the establishment of quality assurance systems that comply with various standards, minimize defects, and maintain competitiveness in rapidly changing markets.

Focused on strategic partnerships to enhance customers’ competitiveness and sustainability

High-precision measuring instruments are the cornerstone of quality control in manufacturing. Any deviation in measurement accuracy can lead to defective products, delivery delays, and diminished customer confidence. Mitutoyo places great emphasis on the regular maintenance, inspection, and repair of its equipment to ensure long-term performance and accuracy, fully supporting customers’ quality assurance systems.

With a network spanning over 30 countries, Mitutoyo has established service operations certified to local national standards, allowing customers to access consistent, high-quality support worldwide. Continuous after-sales service strengthens customer relationships and supports stable production, enabling clients to maintain competitiveness and gain strategic advantages.

Mitutoyo also offers a new global service contract that monitors the condition and performance of customers’ measuring instruments. This enables early problem detection and preventive maintenance, reducing production downtime and preventing defects.

Mitutoyo’s after-sales service goes beyond product support; it represents a strategic partnership that enhances quality, competitiveness, and sustainability, empowering customers to operate confidently in global markets.

“Advancing Sustainability” Through Proactive Premium after-sales Support

Mr. Hiromiki Goto

Director – Sales Division of Sodick (Thailand) Co., Ltd.

Japanese Automotive Innovation: Leading the World into the Future with Sustainable Technology

Over the past two decades, hybrid electric vehicles (HEVs) have been widely regarded as one of the most suitable mobility solutions within the automotive industry, playing a significant role in reducing CO₂ emissions through highly practical real-world performance. HEVs offer an optimal balance between conventional energy infrastructure and electric-drive efficiency, making them a viable technology for many global markets.

Today automakers are increasingly confronted with a diverse range of propulsion options, including battery electric vehicles (BEVs), HEVs, plug-in hybrid electric vehicles (PHEVs), biofuel vehicles, and hydrogen fuel-cell electric vehicles (FCEVs). Each alternative presents varying levels of suitability depending on regional characteristics, driving behaviors, infrastructure readiness, and environmental conditions. Meanwhile, battery technologies continue to advance in terms of charging speed, energy density, driving range, and service life. Despite these advancements, the overall environmental impact of batteries—from manufacturing and logistics to end-of-life disposal—remains substantial. As a result, automakers must carefully develop products tailored to the needs and circumstances of each market rather than pursuing BEVs alone, ensuring alignment with the broader energy ecosystem of each region.

For automotive suppliers, the current landscape presents both challenges and opportunities. For example, in Thailand, certain EV manufacturers import most components and conduct only final assembly domestically, thereby limiting the economic contribution to the local supply chain. Conversely, if internal combustion engines (ICE), HEVs, or hydrogen-powered vehicles continue gaining market adoption.

Thai suppliers would have greater opportunities to participate more deeply in the industryʼs value chain. Therefore, the Thai government plays a critical role in defining an optimal industrial strategy- balancing EV promotion while strengthening domestic capabilities in other technology domains that remain relevant in the global market. Strategic measures to support suppliers in upgrading technology, developing human resources, and reinforcing the production ecosystem will be essential to sustaining competitiveness and employment, ultimately guiding the industry toward long-term growth and carbon-neutral mobility.

Die-Sinker & Wire-Cut EDM: Pioneering Solutions for End-to-End Automotive Parts Manufacturing

Our Die-Sinker and Wire-Cut EDM machines are essential for producing critical components in electric vehicles (EVs), including sensors, battery cases, motors, and body parts. Renowned for their high precision, excellent surface finish, and capability to handle complex geometries, these machines are equally vital for hybrid and internal combustion engine (ICE) vehicles.

The Die-Sinker EDM delivers exceptional accuracy and stable performance for intricate molds and components, while the Wire-Cut EDM offers superior cutting precision, ideal for fine parts such as connectors and micro-sensors.

Meanwhile, our Injection Molding Machines address the industry’s shift from metal to plastic components – particularly in ICE vehicles – providing lightweight, durable solutions with excellent dimensional stability.

As demand for compact, high-precision parts grows in EV manufacturing, our technologies support production across every segment – from sensors and motors to structural components – helping to drive the automotive industry toward a more efficient, sustainable, and innovative future.

Driving Sustainability Through Exceptional After-Sales Service

At Sodick, after-sales service and customer support are at the core of our business philosophy. Machine breakdowns can disrupt production and create significant losses, so providing reliable, prompt, and proactive support is essential.

Our team of highly trained service engineers is ready to respond quickly on-site, supported by a well-stocked inventory of spare parts to minimize lead times. Beyond repairs, we focus on preventive maintenance and operator training – both at customer facilities and in our training centers – to ensure ma-chines operate at peak performance and operatorsʼ skills continually improve.

Through these efforts, we not only maintain optimal machine performance but also build strong, trust-based relationships with our customers. This close partnership allows open communication and ensures we deliver the highest standard of support, reflecting Sodick’s commitment to excellence in every aspect of service.

“Advancing Sustainability” Through Proactive Premium after-sales Support

Mr. Kamihito ( Jin ) Kakegawa

Managing Director of Sumitomo Electric Hardmetal (Thailand) Ltd.

Japanese Automotive Innovation: Leading the World into the Future with Sustainable Technology

As widely recognized, the battery electric vehicle (BEV) market in Thailand has experienced remarkable growth, led in particular by the expansion of BYD, whose sales have more than doubled year-on-year. This trend reflects both the strong momentum of electric mobility and the influence of competitive pricing. However, the current market structure remains heavily concentrated in the upper-segment consumer group, where BEVs are primarily purchased as a second vehicle. As a result, once this early wave of enthusiasm begins to stabilize, market growth is expected to moderate.

Despite strong market acceptance of Chinese BEVs—credited for their affordability, modern styling, and premium interior design—there is growing concern regarding after-sales service quality, spare-parts availability, and long-term durability. These factors have become increasingly important to Thai consumers when evaluating the long-term value of ownership. In addition, challenges related to compliance with government incentive requirements, including local production content and spare-parts provisioning, have yet to be fully resolved, keeping the market in a period of transition.

Against this backdrop, the revised excise tax policy for hybrid electric vehicles (HEVs), scheduled to take effect in 2026, is anticipated to serve as a key catalyst for the renewed growth of Japanese automakers—long recognized for their expertise in hybrid technologies. Several Japanese manufacturers have already begun preparing production plans to accommodate future demand, which is expected to diversify market offerings and help balance the coexistence of both full-electric and hybrid technologies in alignment with Thailandʼs infrastructure landscape.

In this context, our company is committed to providing comprehensive support in technology, manufacturing, and after-sales service. We aim to strengthen the competitiveness of Thailandʼs automotive supply chain and contribute to the development of a resilient, world-class industry capable of achieving sustainable growth on the global stage.

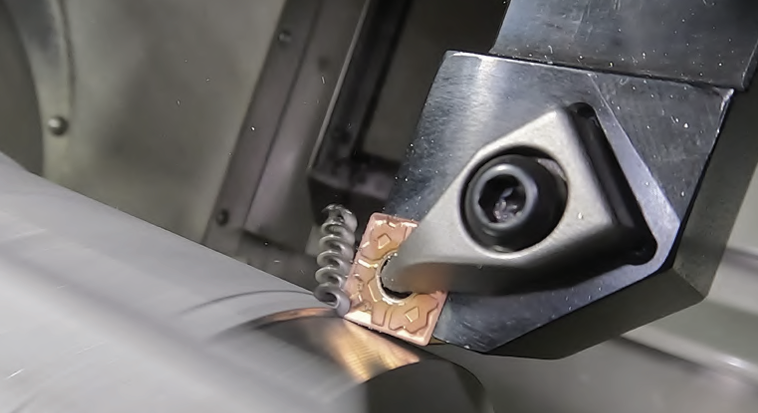

Driving Innovation Through Change: Our Edge in Thailand’s Cutting Tool Market

In recent years, Thailandʼs cutting tool market has become increasingly diverse, with more international manufacturers introducing new product options to local industries. While this evolving landscape brings competitive challenges, it also presents opportunities for market participants to elevate technological standards and enhance service quality. Our company has been rooted in the cutting tool industry for over a century, accumulating extensive technological expertise and continuously advancing innovations to address the growing complexity of modern manufacturing. Our core strengths include consistent product quality, the development of state-of-the-art technologies, and comprehensive service offerings—from application consulting and tool selection to after-sales support.

In material and coating technology, our research and development efforts have yielded outstanding results. Notable examples include the AC9115T and AC9125T grades, specifically engineered for titanium machining. These grades utilize a specially formulated tungsten-carbide composite and have been patented within the industry. Another key innovation, AC1135U, is widely recognized in the Thai market for small stainless-steel workpieces. With its specialized thin-film coating and advanced surface treatment, it effectively reduces built-up edge and enhances machining stability.

We remain committed to closely monitoring technological advancements and evolving market needs, ensuring that our products and services continue to deliver real value to the industrial sector. Our mission is to support manufacturers in improving machining efficiency, reducing operating costs, and building long-term confidence through reliable solutions and professional service. Through this commitment, our company aims to be a trusted partner to the manufacturing community—working alongside customers to advance quality, optimize processes, and strengthen competitiveness in a sustainable manner.

Empowering Thailand’s Manufacturing Sector with Global-Standard Technical Centers and Comprehensive Cutting-Tool Solutions

Our key strength lies in operating a dedicated tooling manufacturing facility designed specifically to serve the Thai market. We focus on producing drills, carbide inserts, CBN/PCD inserts, and ultra-small turning tools, all of which can be customized with high flexibility to meet unique customer requirements. With localized production, we are able to respond quickly to shifting market needs, support customers with shorter lead times, ensure production stability, and enhance the overall competitiveness of Thailandʼs manufacturing industry.

In addition, we provide rapid re-grinding and recoating services, covering a wide range of coating types including DLC coating to extend tool life, reduce cost per component, and maximize long-term return on investment. These services are engineered to accommodate diverse machining applications while maintaining consistent tool performance under demanding operating conditions. Within our facility, we have also established a fully equipped Technical Center featuring Machining Centers and multifunctional automatic lathes for real-world cutting trials. The center also serves as a venue for ongoing technical training programs, supported by experienced engineers who provide hands-on consultation. These initiatives have been highly valued by customers, as they enhance machining knowledge, improve production practices, and support informed tool selection aligned with specific application needs.

Beyond product development, we are committed to offering comprehensive tooling support aimed at reducing cycle time and effectively accommodating new projects. Backed by extensive experience gained in Japan and global markets, we deliver tailored tool selection strategies and machining solutions to each customer. Our goal is to help manufacturers elevate productivity, reduce operating costs, and build sustainable confidence in the long term. We remain dedicated to supporting our customers in elevating Thailandʼs manufacturing standards to meet global benchmarks.

- Article by: MEGATech &

- JTEKT Machinery (Thailand) Co., Ltd. << Click Here

- Mitutoyo (Thailand) Co., Ltd. << Click Here

- Sumitomo Electric Hardmetal (Thailand) Ltd. << Click Here

- Sodick (Thailand) Co., Ltd. << Click Here