“R.P.S. SUPPLY Co, Ltd.” is the name that comes with reliability and trust for over 30 years as the one-stop distributor and service provider of industrial products used for welding, cutting, bending and rolling. It began with the great executive Mr. Pornsak Pongsakornvanich, Managing Director, and the visionary, trend-setting executive Mr. Pongsakorn Pongsakornvanich, with the idea to be the leader in welding and the professional reseller of industrial machinery for metalworks.

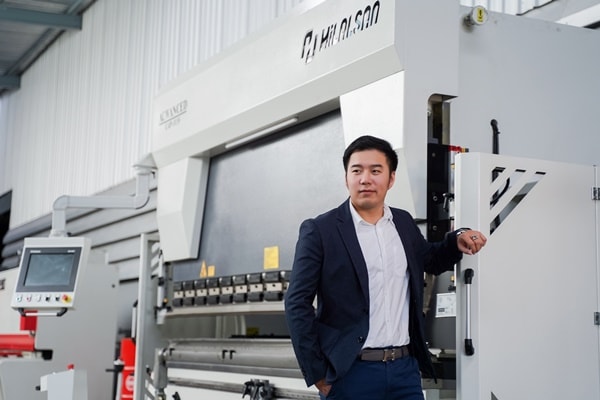

Mr. Pongsakorn Pongsakornvanich, Director of “R.P.S. SUPPLY Co., Ltd.” says that R.P.S. SUPPLY Co., Ltd. was established in 1990 and began with importing as well as being an authorized reseller of welding products, tools for technicians and all kinds of welding tools and large machinery in industries such as gas cutters, plasma cutters, CNC cutters, cutters, press brakes, rolling machines and tube benders.

Our company started with trust from many world’s leading brands to allow us to be their authorized resellers such as HUAWEI, KEMPPI, HITRONIC, and ESAB. We also invent and develop our own products under the brand UMINI which are well received. These products are reliable and have gained trust from various organizations, both public and private, especially when it comes to welding because we are a one-stop-shop for welding works. Come to us and you can get everything you need.

“Our company can install the machinery and we also offer aftersales service with our experienced teams specializing in each type of machinery so our customers can be assured that when they buy a product from us, they will get maintenance from a team of specialists through the product lifetime. Our company is committed to expanding the range of our products to cover all kinds and all levels to meet the different needs of different customers. Our sales teams are well trained to present the products and to give the best advice and there are teams to install and repair the machines. We also have spare parts in stock. So, we are truly the one-stop-shop.

Moreover, we have expanded our service and we now have a branch in Khon Kaen to provide quick services to customers in the Northeast of Thailand. We are planning to expand to other regions in the future.”

HILALSAN… CNC PRESS BRAKE ADVANCE CAP 3135

Mr. Pongsakorn continues by saying that with quick advances and new trends in the world today, the company will never stop looking for the best quality products with high technology and innovations to meet the demands of the customers. With the foresight of the opportunity for growth in the metalworking industry, the company now resells the machinery in the Sheet Metal Expo. We have selected high-quality machines from the brand ZYMT (China) and from the brand HILALSAN (Turkey) to sell in Thailand.

HILALSAN has been a manufacturer of machinery for 36 years with European quality and standards at an affordable price. The quality exceeds the price. To illustrate, HILALSAN CNC PRESS BRAKE ADVANCE CAP 3135 is outstanding because of these features

GENERAL FEATURES

– The machine frame is manufactured with the advanced technology with very precise tolerances and stress relieved with large welded components. All tensile points are designed with large radii and strain accumulation and possible welding cracks are eliminated.

– The hydraulic cylinder is designed as double-sided and honed to surface quality of 2 microns. Thus, minimum wear resistance is created for the felts. The cylinder bodies are manufactured as SAE 1040 material forged.

– Backgauge system is manufactured in accordance with environmental conditions. Backgauge bearings are made for heavy conditions with double bearers. Scrapping type bearings are used against dust and other particles that will accumulate in the linear guideways against dusty environmental conditions.

Leading Technology… MOTORS & DRIVERS

The movement of the backgauge is operated by the CNC control unit in hydraulic press brakes. The high performance servo motors produced by Mitsubishi move the bearing axes. Precision parts are produced by these motors. The electrical circuit components used are Siemens, Telemecanique and Schneider brand products.

CNC PRESS BRAKE

The most important factor for precision bending in press brakes is the Backgauge system.

Hilalsan design features a special, powerful and precise backgauge system that works on linear guideways at side counters and large-sized ball screws. The special design has very strong construction due to its strong mechanical structure and can withstand large loads.

The backgauge finger blocks move on top of the double-rail and aluminum-plated top profile. These backgauge finger blocks are very sensitive and can be adjusted from any point.

“We emphasize the variety of products so that customers can come to us and find all the right products, right here. We also have teams to offer accurate information quickly and we are expanding the score and the range of our products to offer services to meet all the requirements of the customers. We train and develop our teams to continue to increase the efficiency of our services. So, we are confident that we will deliver the best product and the best service to our customers,” concludes Mr. Pongsakorn.