As competition in manufacturing and logistics continues to intensify, many organizations are turning to automation to enhance efficiency, reduce human errors, and lower labor costs. One of the fastest-growing technologies in the industrial sector is AMR KENMEC, or Automated Mobile Robots, which serve as intelligent autonomous transport systems.

Benefits of AMR KENMEC Autonomous Mobile Robots in Factories

- Reduce labor costs: AMRs can replace manual material handling inside the factory.

- Enhance safety: Lower the risk of workplace accidents.

- Increase productivity: Operate continuously 24/7.

- Reduce internal transport time.

- Integrate with WMS or ERP systems.

- Improve flexibility across the supply chain.

AMR KENMEC by SWX Logistics Solutions

The KENMEC AMR autonomous mobile robots can navigate independently using intelligent navigation technologies such as SLAM, LiDAR, and various sensors. This enables the robots to avoid obstacles, learn their environment, and adapt intelligently—unlike older AGV systems that rely heavily on magnetic tapes or QR codes.

With these capabilities, KENMEC AMRs play a crucial role in:

- Large warehouses

- Industrial factories

- Distribution centers

- Production lines requiring continuity and safety

As the official distributor of KENMEC Automation, one of Asia’s leaders in robotic solutions, SWX Logistics Solutions offers a complete range of AMR products—from basic transport, pallet handling, high-lift AMRs, and conveyor integration to customizable AMR platforms.

This article summarizes all KENMEC AMR models, including specifications, key features, and suitable applications, helping you choose the best solution for your factory.

Why Choose AMR Automated Mobile Robots from KENMEC?

KENMEC designs AMRs to meet diverse logistics requirements inside factories, with focus on four core factors:

1. Heavy-load capability

Supports loads from 400 kg to 2,000 kg, ideal for heavy industries like automotive parts, steel components, or industrial goods.

2. Operation in narrow aisles

Many KENMEC models can operate in aisles as narrow as 2,000–2,200 mm, helping increase storage density.

3. High safety standards

Each unit is equipped with:

- 360° LiDAR

- Bumper protection

- Emergency Stop function

- Pallet detection sensors

- Warning lights + safety bumpers

4. High precision

With SLAM navigation and advanced sensors, AMRs achieve ±10 mm accuracy in pickup/drop-off points.

List of AMR Autonomous Mobile Robots from KENMEC

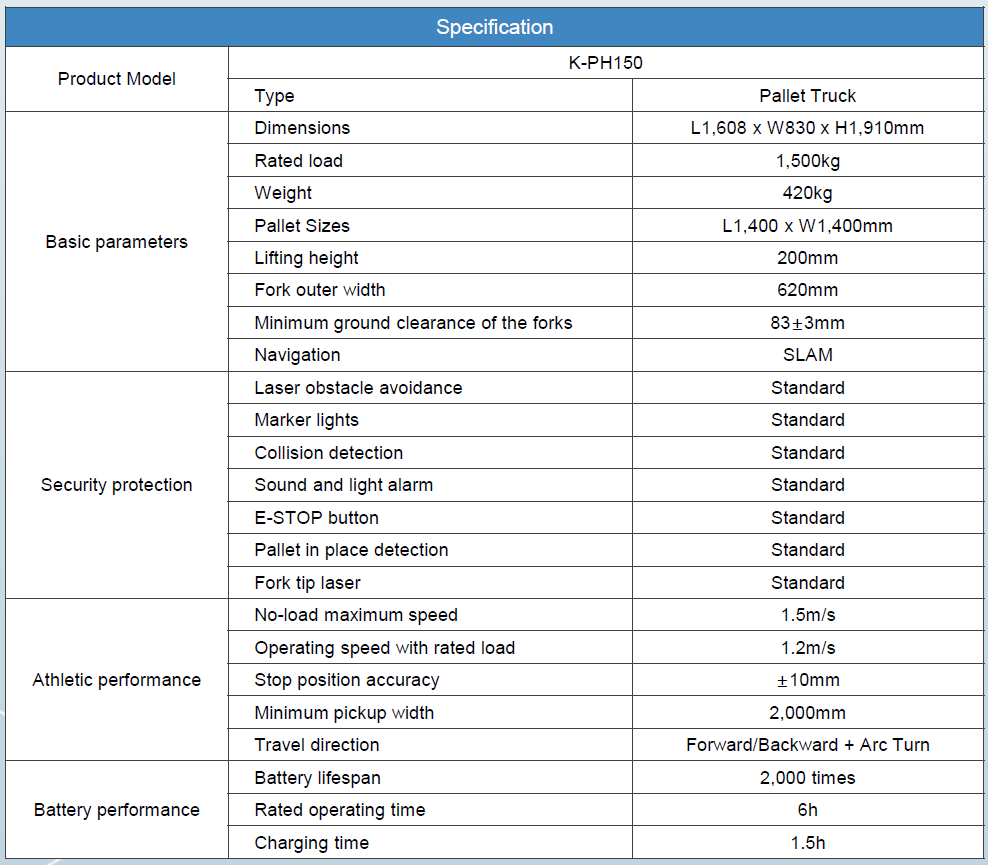

1. K-PH150 – Pallet Truck AMR for Narrow-Aisle Warehouses

Ideal for warehouses aiming to increase storage space and reduce manual pallet handling. Compact, easy to maneuver, and highly safe.

Key Features — K-PH150 Pallet Truck AMR

- Load capacity: 1,500 kg

- Minimum pallet pickup distance: 2,000 mm

- Maximum speed: 1.5 m/s

- Stopping accuracy: ±10 mm

- Navigation: SLAM

- Full safety sensor package

Suitable for:

- Space-limited warehouses

- General pallet transport

- Automated storage systems for SME–Enterprise factories

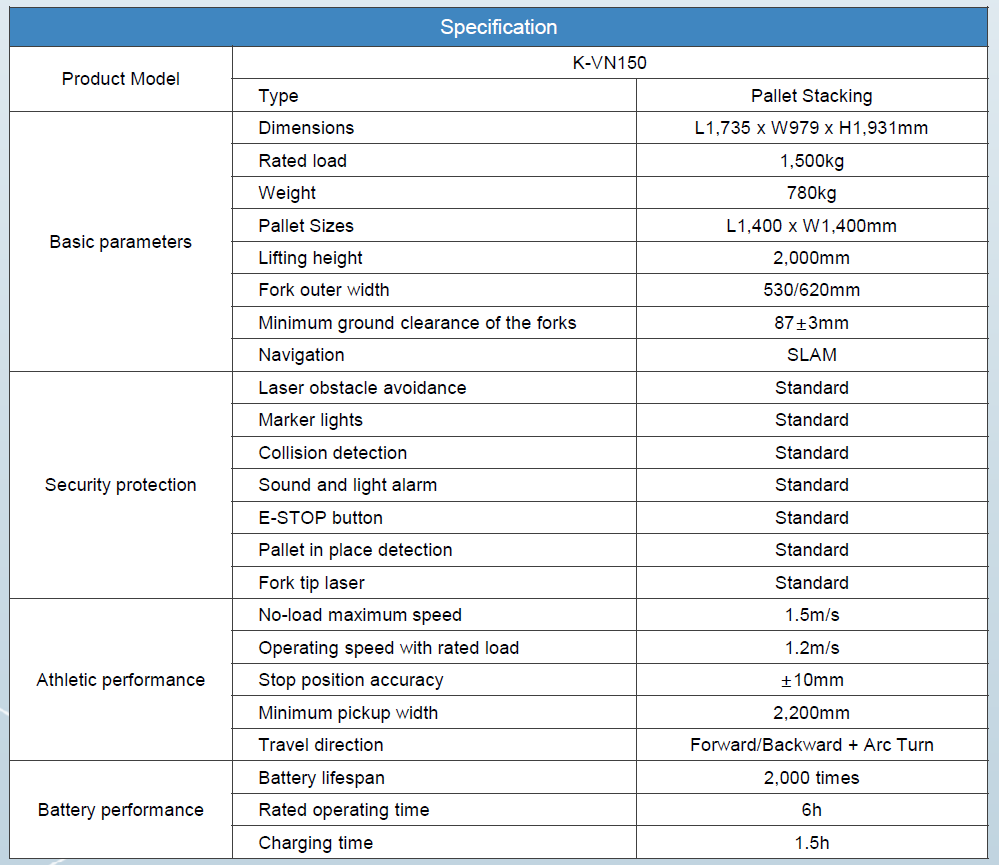

2. K-VN150 – Pallet Stacking AMR (Lifting up to 2 meters)

Acts like an automated stacker for operations requiring 1–2 level lifting and increased vertical storage.

Key Features — K-VN150 Pallet Stacking AMR

- Load capacity: 1,500 kg

- Lift height: 2,000 mm

- Aisle width: 2,200 mm

- Speed: 1.5 m/s

- Full safety package

Suitable for:

- Medium rack warehouses

- Shelf-to-shelf pallet transfer

- Factories starting automation with simple requirements

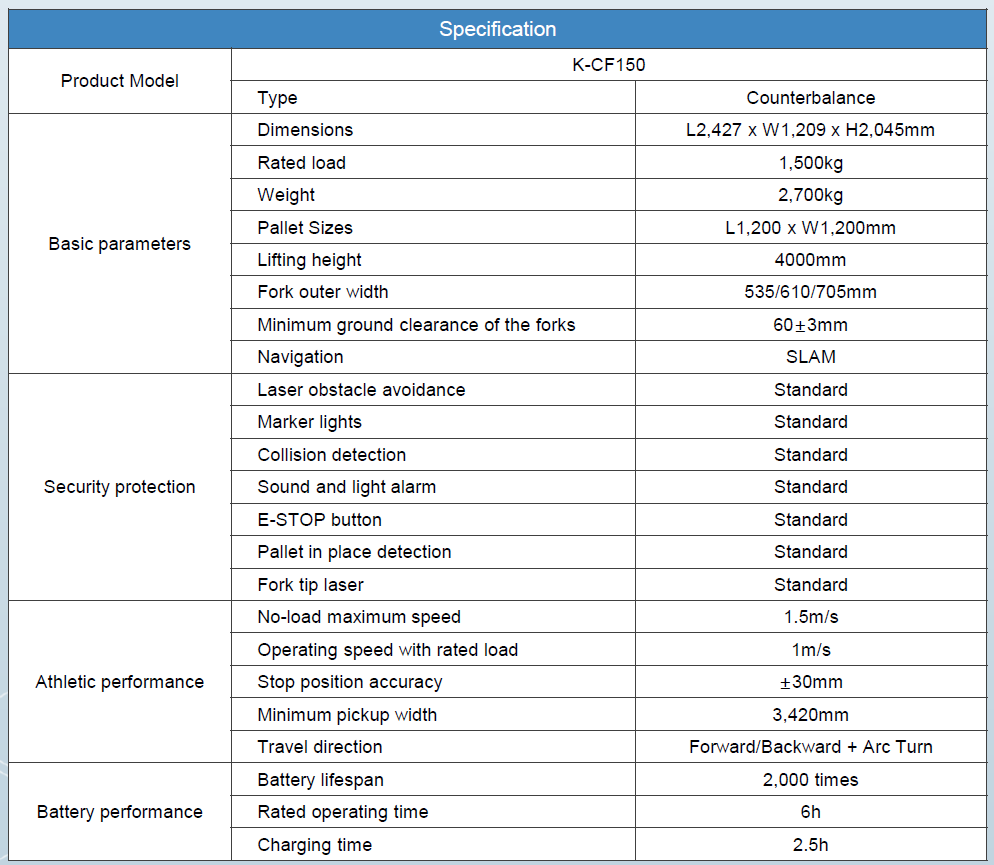

3. K-CF150 – Counterbalance AMR (Lifting up to 4 meters)

A model designed to replace driver-operated forklifts—ideal for heavy-duty environments.

Key Features — K-CF150 Counterbalance AMR

- Load capacity: 1,500 kg

- Lift height: 4,000 mm

- Heavy-duty chassis

- Pallet detection sensors

- Accuracy: ±30 mm

Suitable for:

- Loading dock transfer

- Production line lifting

- Industrial warehouses requiring strength and safety

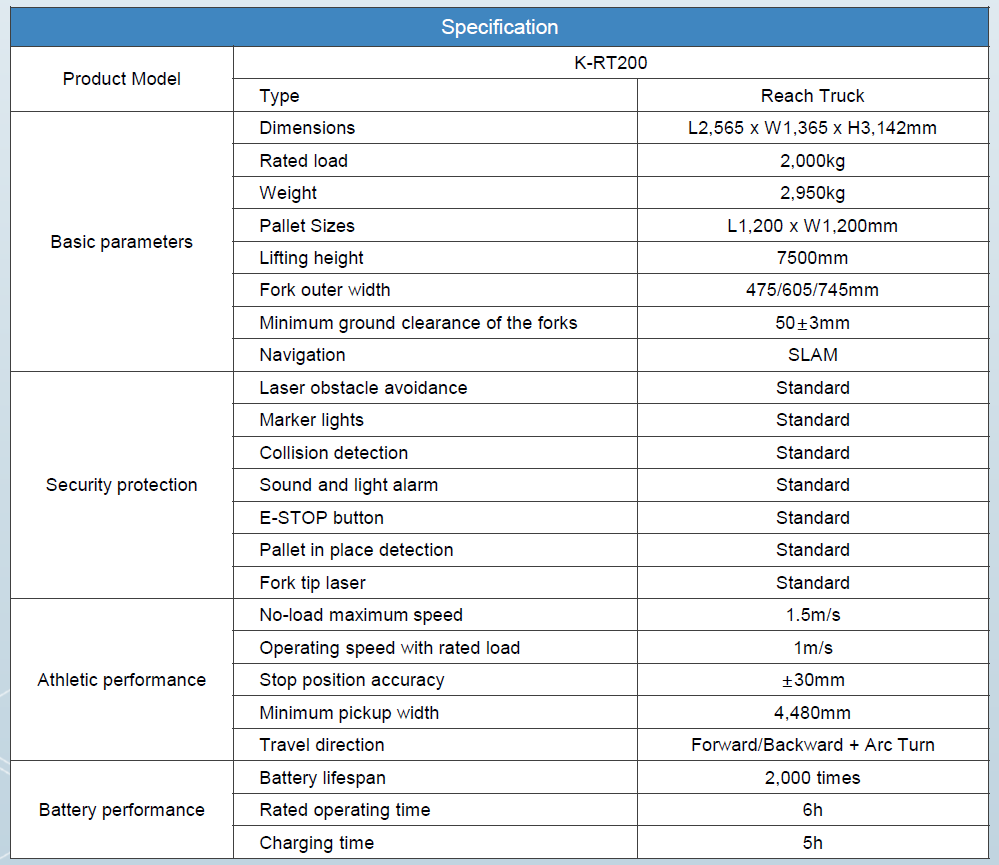

4. K-RT200 – Reach Truck AMR (Lifting up to 7.5 meters for High-Bay Storage)

One of the tallest KENMEC models, engineered for warehouses requiring very high vertical storage.

Key Features — K-RT200 Reach Truck AMR

- Load capacity: 2,000 kg

- Lift height: 7,500 mm

- High stability at maximum height

- Ideal for multi-level high-bay warehouses

- Stopping accuracy: ±30 mm

Suitable for:

- High-bay modern warehouses

- High-speed logistics operations

- Large-scale warehouse automation

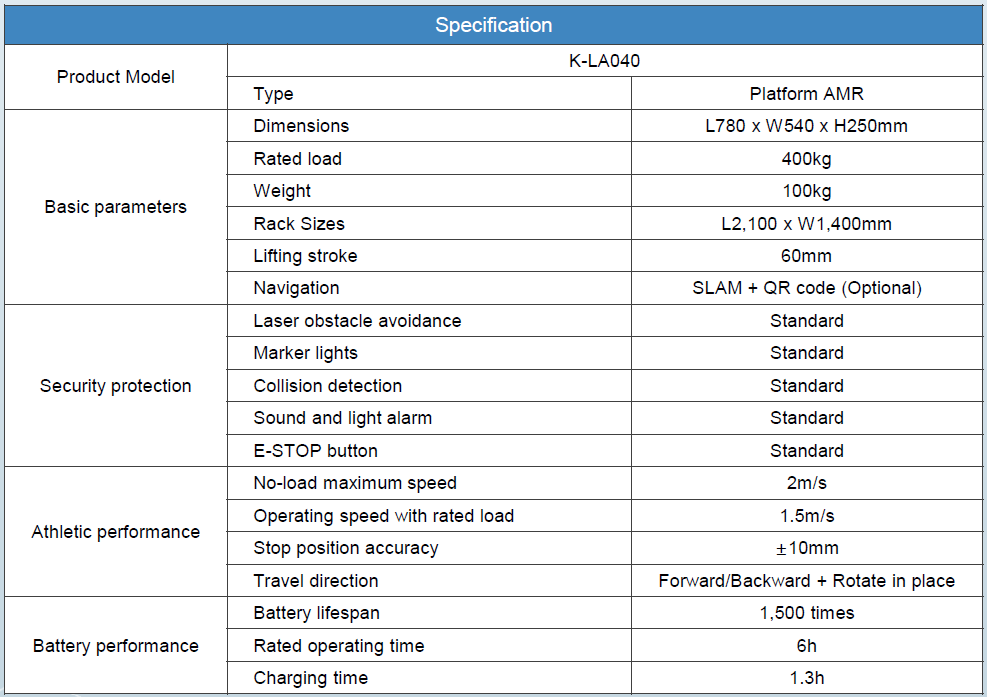

5. K-LA040 – Platform AMR (400 kg Load)

Designed for adding custom mechanisms such as racks, containers, or automation modules requiring high speed.

Key Features — K-LA040 Platform AMR

- Load capacity: 400 kg

- Max speed: 2 m/s

- Can rotate in place

- Navigation: SLAM + optional QR

Suitable for:

- Assembly lines

- Small to medium parts handling

- Electronics and OEM factories

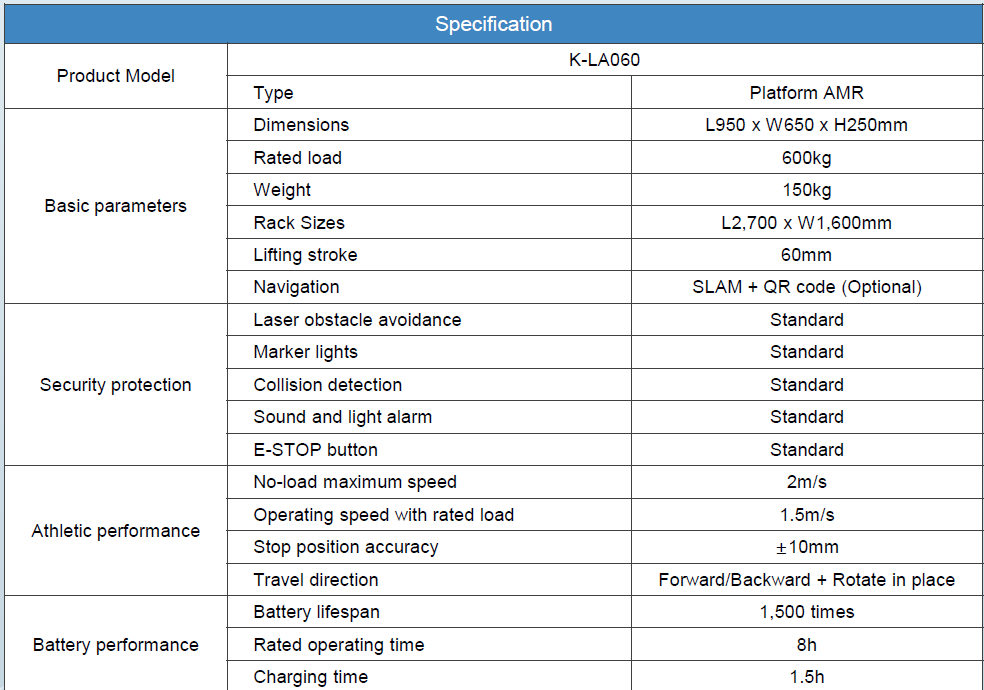

6. K-LA060 – Platform AMR (600 kg Load)

A more robust version of LA040 for heavier applications.

Key Features — K-LA060 Platform AMR

- Load capacity: 600 kg

- Speed: 1.5–2 m/s

- 8-hour continuous operation

- Flexible customization options

Suitable for:

- Production line material transfer

- Short-distance conveying

- Various industrial component assembly

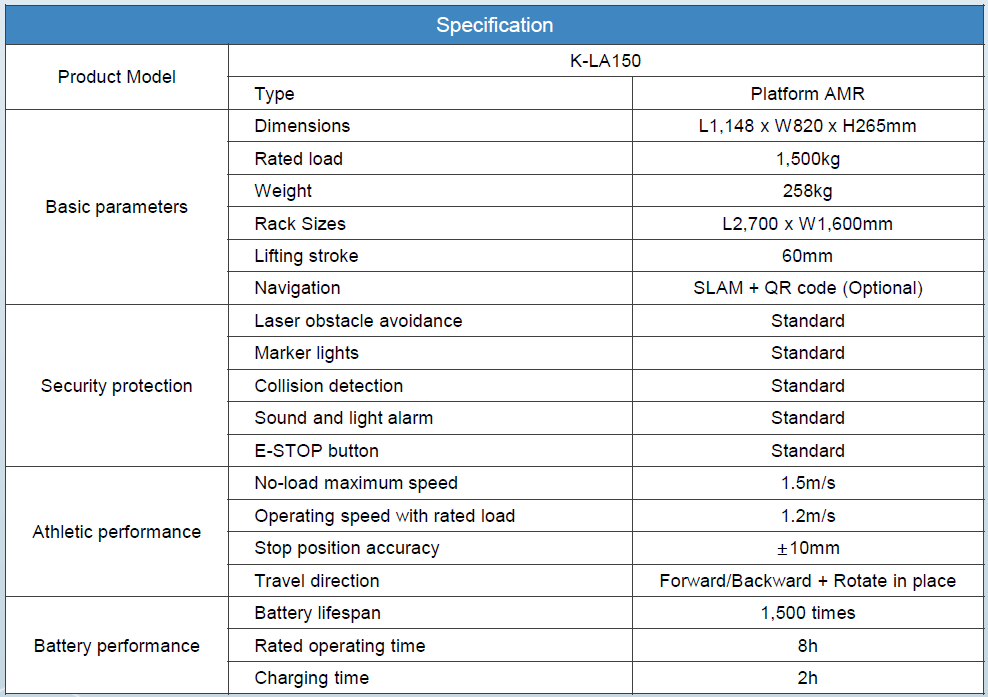

7. K-LA150 – Platform AMR (1,500 kg Load)

A heavy-duty platform AMR with high flexibility.

Key Features — K-LA150 Platform AMR

- Load capacity: 1,500 kg

- Reinforced structure

- Efficient in narrow aisles

- Supports multiple accessory modules

Suitable for:

- Heavy raw material handling

- Heavy-load transport inside production lines

- Heavy industrial automation

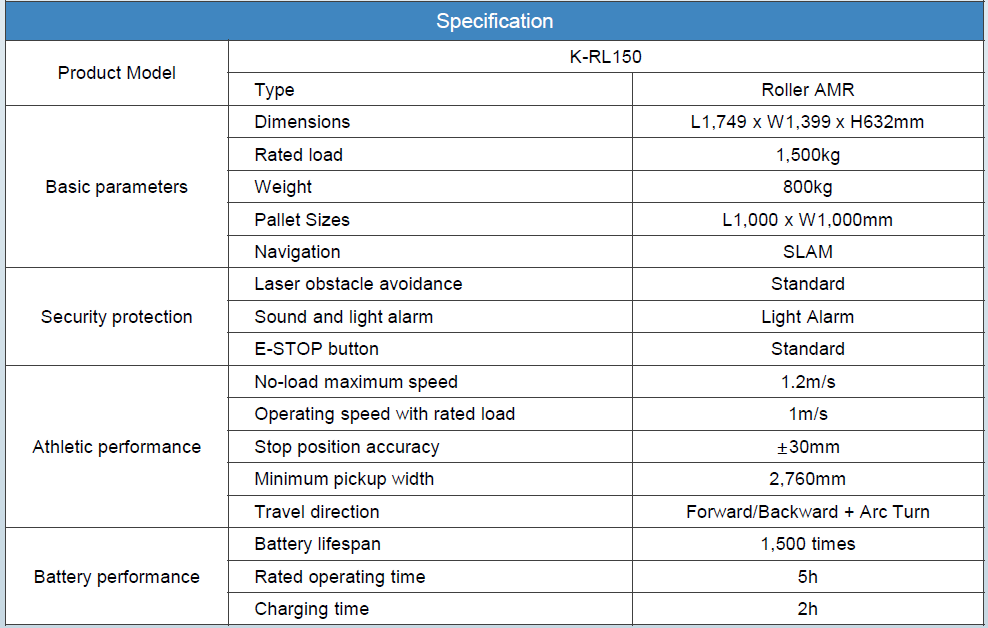

8. K-RL150 – Roller AMR for Conveyor Integration

Additionally, it is designed specifically for seamless connection with conveyor systems—ideal for continuous production lines.

Key Features — K-RL150 Roller AMR

- Load capacity: 1,500 kg

- Fully compatible with conveyor systems

- Reduces manual handling at material transfer points

- Stopping accuracy: ±30 mm

Suitable for:

- Automated production lines

- Interfaces between production and packing lines

- Factories focused on reducing downtime and increasing flow continuity

Summary: KENMEC AMR — The Ideal Automation Solution for Industry 4.0

Moreover, whether you need pallet transport, high-lift operations, narrow-aisle navigation, or conveyor integration, KENMEC AMRs offer models for every workflow. They provide high safety, continuous operation, and long-term cost savings.

For factories transitioning into Industry 4.0, AMRs deliver true improvements in speed, accuracy, and labor reduction.

SWX Logistics Solutions — Official Distributor of KENMEC AMR in Thailand

As the official distributor of KENMEC, SWX Logistics Solutions provides internationally certified AMR solutions for factories and warehouses across Thailand, along with end-to-end services including consultation, system design, installation, and after-sales support.

With the partnership between SWX Logistics Solutions and KENMEC, customers are guaranteed:

- Authentic products with global standards

- Accurate technical specifications from the manufacturer

- Local technical support in Thailand

- Consistent spare parts and service availability

- Systems aligned with official factory standards

- In addition, we offer expert support in both technical and system planning.

SWX Logistics Solutions offers full-cycle services:

- Expert consultation and problem analysis

- AMR system design based on real factory layout

- Installation and integration with production lines

- Onsite staff training

- After-sales service and long-term maintenance

- Future system expansion support

This makes SWX Logistics Solutions a reliable choice for factories seeking high-quality KENMEC AMR solutions in Thailand.

Our specialists are ready to provide consultation. Contact SWX Logistics Solutions:

- Head Office: No. 2, Jasmine City Building, 22nd Floor, Zone C, Soi Prasanmit, Sukhumvit Road, Khlong Toei Nuea, Watthana, Bangkok 10110, Thailand

- Tel.: 094 769 6941

- E-mail: sales@swxautomation.com

- ID LINE: swx.co.ltd

- Website: swlogisticsth.com << Click Here

Article by: SWX Logistics Solutions << Click Here