Shaft measuring systems are essential for ensuring the precision and accuracy of rotating parts. Components like turbochargers, engine valves, and medical implants, can impact performance and safety where even minor deviations occur. To level up safety standards, shaft measuring technology was developed to ensure that shafts and related components meet design specifications and intended functionality.

MEGA Tech take a full survey of the new Shaft measuring systems from Jenoptik that will ease the life of many of you in high-end machined part manufacturing, the QC inspectors in particular.

Why Shaft Measuring Systems are Needed?

Shafts and other rotationally symmetric parts used in jet engines or life-supporting equipment are expected to be free of any discrepancies. So, they require very tight tolerances. Shaft measuring systems, especially optical and multi-sensor systems, can achieve micron-level accuracy, ensuring these parts meet stringent specifications. Automated shaft measurement systems can perform multiple measurements on a single setup, significantly reducing inspection time compared to manual methods. This efficiency is crucial for high-volume production environments.

Modern shaft measurement systems can accommodate a wide range of part geometries and sizes, making them ideal for diverse applications. Some systems can even combine optical and tactile (touch probe) measurements for comprehensive inspection. Shaft measurement is vital for quality control, ensuring that manufactured parts meet customer requirements and industrial standards as intended. It minimizes QC inspector’s intervention thus reducing human error, ensuring consistent and reliable measurements regardless of the operator’s skills. Other benefits include cost reduction, process optimization and improved overall efficiency.

Optimum Productivity and Quality

In the past, a quality control inspector would have taken a random selection of finished shafts back to his or her room and begun the painstaking process of examining every aspect of them using calipers or micrometers. Measurements would have been jotted down and compared with acceptable tolerances.

Over time, quality control methods have evolved to reduce these time-consuming routines. Today, optical shaft metrology is at the very forefront of this evolution, making it the cutting edge of product evaluation and quality assurance. Furthermore, optical shaft metrology units can be installed right after the cutting machine on the factory floor, cutting out that journey to the quality inspector’s room.

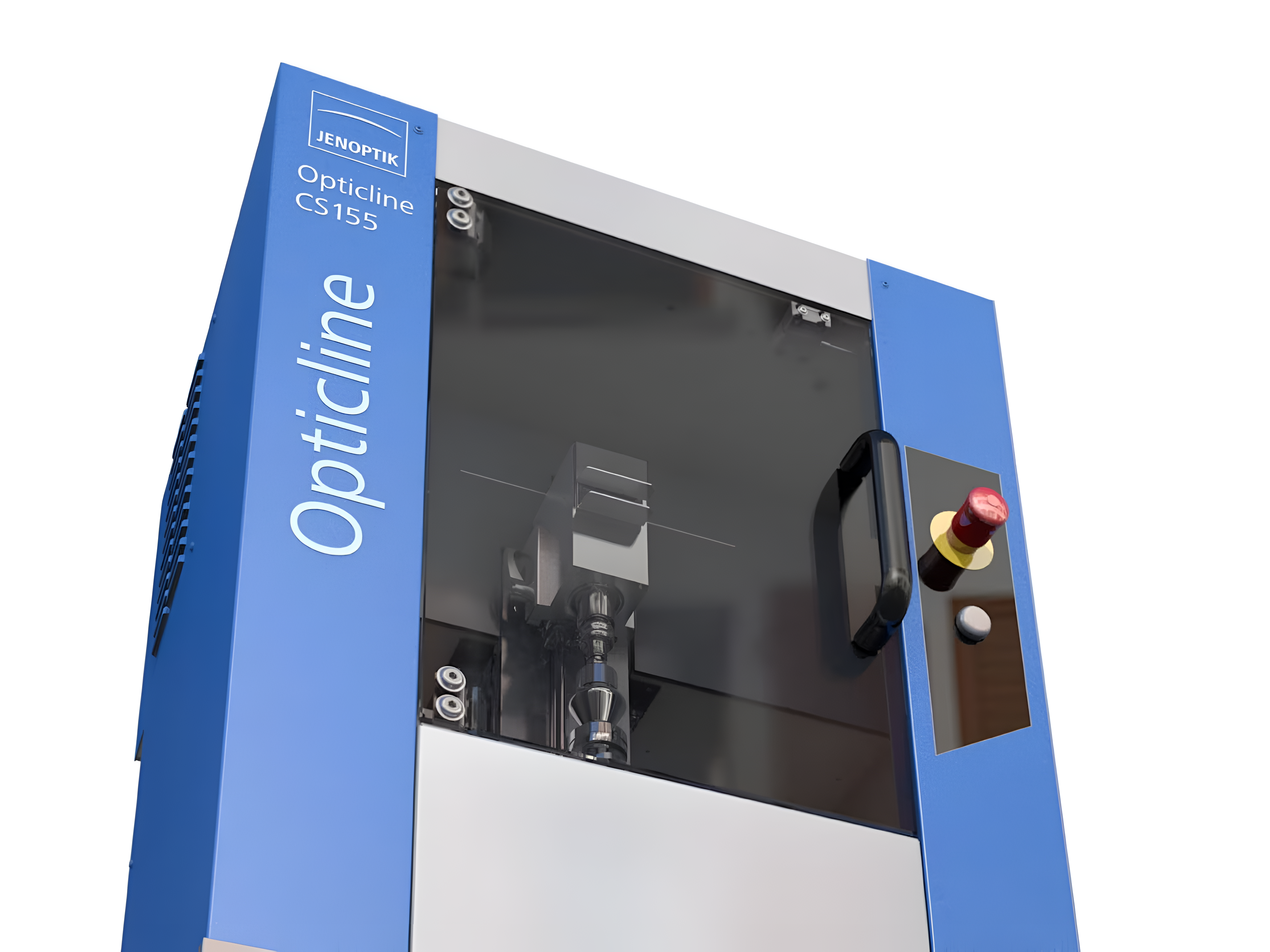

Opticline C Series Designed for Long-Term GR&R

Opticline C Series shaft measuring systems offer maximum gauge repeatability and reproducibility over time, ensuring consistent and reliable results. Optical shaft measuring technology uses non-contact optical sensors to precisely measure the dimensions and features of rotating shafts and cylindrical parts. The shaft measuring systems are widely used in manufacturing for quality control, particularly in industries like automotive, aerospace, and medical technology.

The System features optimum precision properties in μm delivering measurements within seconds. An individual camera offers bidirectional measurement for workpiece diameters of up to 80 mm, and scaling of the optical system for measuring diameters of up to 140 mm without loss of resolution or quality. The system features special tailstock and headstock, and simple and automatic workpiece alignment, enabling rapid workpiece changes while offering maximum precision.

Easy Setup for Maximum Workflow

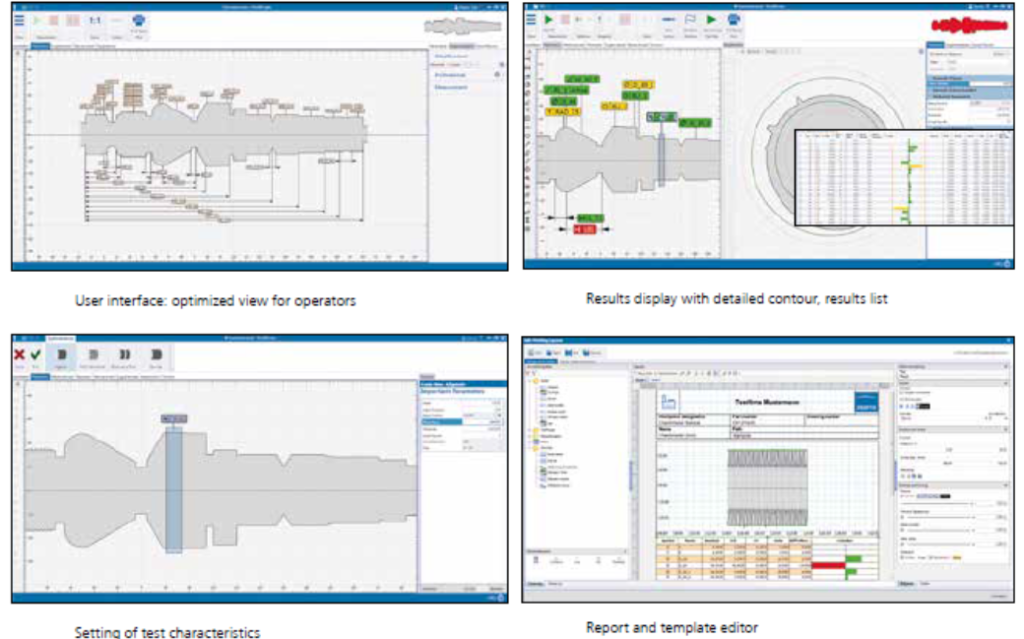

The Opticline C Series is designed to optimize workflow and quick and easy setup. If measurement programs have not yet been created, the part is loaded, scanned fully or user-defined, and then the part profile is stored. This process takes only a few seconds. Immediately thereafter, the desired feature can be selected with a simple mouse click-define control settings such as nominal values and tolerances. On average, a new program with about 20 features can be created in only 5 minutes.

This robust and reliable system can be used in manufacturing itself, or in the measuring room. They even function without any problems in the production areas with tough environments.

Analysis and Reporting with Software Tolaris Optic

The system features new measuring and analysis software Tolaris Optic which is optimally adapted to user requirements in terms of operation and interface design. The Tolaris Optic software has been a proven success for all measuring systems of the Opticline range. It offers comprehensive analysis and reporting functions, as well as many additional functions. The measurement results are available within just a few seconds. You can display, print out, save, or export them via the integrated interfaces.

Conclusion

The Opticline C Series helps you to complete your measuring tasks– from the creation of the test plan to completing the pilot test in a fast and easy manner. For many years, the Opticline range of measuring systems has set the benchmark in optical shaft measuring technology. They boast an impressively high measurement speed, accuracy and workflow.

Article by: MEGA Tech & Precision Tooling Services Co., Ltd.<< Click Here