Premium quality industrial products mean more reliability, reduced downtime, safety, and potentially lower long-term costs for the users. For machined part manufacturers, it’s nothing less than the tight tolerance and best surface finishing of the parts. This is when the CNC grinding machine plays a big role.

CNC grinding machines have revolutionized the manufacturing industry by providing precision, efficiency, and reliability in the production of high-quality components. It’s a great honor for MEGA Tech to explore the new G3 Series, universal CNC grinding machines from JTEKT that is regarded as one of the best of its class.

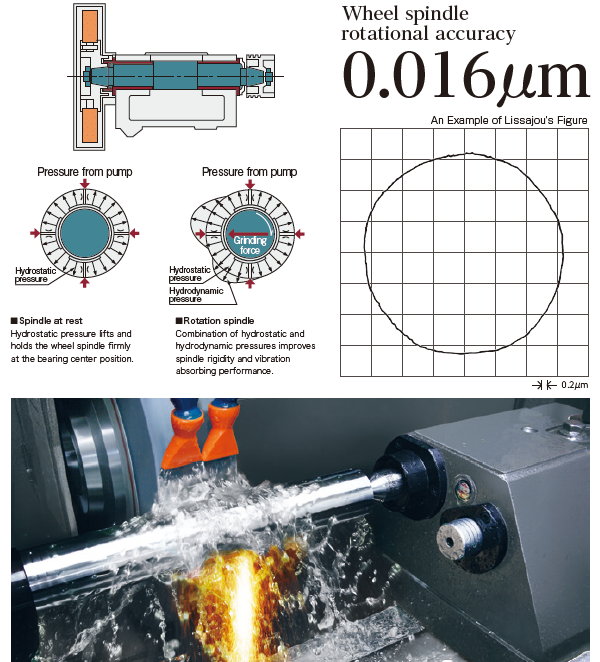

STAT Bearing Is the Heart of the Spindle

Bearings are the heart of spindles because they are essential for their smooth and precise operation. They facilitate rotation by reducing friction between the spindle shaft and its housing, allowing for accurate and efficient movement. Bearings are crucial for maintaining spindle precision, minimizing wear, and ensuring consistent machining accuracy. Efficient bearings also be able to support the radial and axial loads of the spindle, ensuring it can handle the forces involved in machining.

JTEKT‘s STAT BEARING is a key component in their high-precision grinding machines, designed to enhance accuracy and longevity. It combines static and dynamic pressure to create a film of fluid that supports the rotating spindle. By eliminating metal-to-metal contact, the bearing experiences less wear, leading to a longer lifespan. With its highly rigid structure and excellent damping performance, the spindle’s high rotational accuracy of 0.016 micrometers, is practically possible. The STAT BEARING contributes to the overall accuracy of JTEKT‘s grinding machines and is a core technology in their cylindrical grinders and other high-precision machine tools.

G3 Series Grinders

To address labor shortages and the challenge of passing on advanced techniques. JTEKT presents G3 Series, high precision grinding machines with easy user-friendly operation to achieve advanced grinding with simple intuitive operation. The G3 series bed is designed using composite analysis to account for deformation and thermal displacement. As a result, dimensional change of one-third compared to the conventional model.

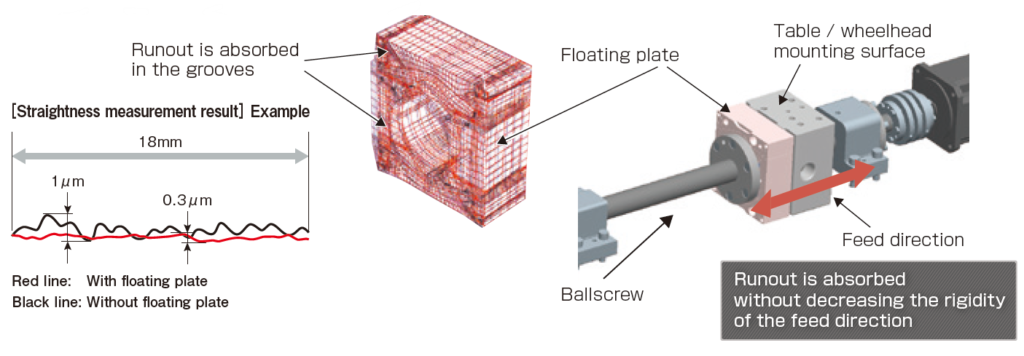

High-accuracy Feed Mechanism

The G3 Series features increased the rigidity of feed direction by supporting the ball screw with high-rigidity bearings. Moreover, a floating plate has been adopted on the wheel head and table to absorb ball screw runout. By absorbing runout while maintaining the rigidity of the feed direction, high feed accuracy improved straightness and surface integrity have been achieved.

Both the wheel head slide and table slide were performed “scraping” by expert technicians. This achieves high straightness, prevents wear of sliding faces and high-accuracy grinding, as well as enables accuracy to be maintained over the long term ensuring the high performance of the machine for an extended period.

Moreover, performing scraping on not only sliding portions, but also the upper side of the table and table mating face achieves stable movement of the spindle head and tailstock, as well as the long-term stability of the table swing.

Expanded Lineup to Fit Diverse Needs

The G3P50 is available in two-unit types. The first unit is for General Purpose, used for grinding workpieces with center holes on both ends or with a chuck. It features a 3-jaw scroll chuck (7’’), and supports both dead and live workhead operation. It offers a practical setup for varied job types while maintaining stability and control. The second unit is specifically for Mass-Production Purposes, designed to achieve faster and more efficient grinding. It must be used with workpieces that have center holes on both ends. This unit is equipped with a dead spindle workhead and an auto-sizer, supporting 3P, ⌀8~⌀80 mm. With a higher wheel surface speed of 45 m/s, this setup increases the production speed and ensures consistent performance.

Japanese Standard Ensures Peace of Mind

Japan transitioned from a nation of skilled craftsmanship to an industrial leader is truly amazing. The same goes for Toyoda as it set new standards in machine tools. Today, JTEKT’s machine tools are considered the best cost of ownership for its customers. JTEKT people take a lot of pride in seeing that their grinders from the late 1980s and early 1990s are still out there running production. That test the construction with the cast iron base which runs a combination of hydrostatic and hydrodynamic wheel head bearings and there’s no metal-to-metal contact when the machine is powered on. It’s one of the few manufacturers that still does the art form of scraping. So, they achieve the tightest tolerances in the market.

With the G3 Series and by JTEKT’s Japanese standard, it’s not exaggerated to say that anyone can effortlessly master advanced grinding.

Article by: MEGATech & JTEKT Machinery (Thailand) Co., Ltd. << Click Here