AI is becoming a key technology for the optimization of production processes. Can and how AI actually help sheet metal fabrication optimizes their operation to increase efficiency and profit? MEGATech look at the real-world AI applications and discover how market leaders use this tool to stand out from the competitions.

AI Algorithms

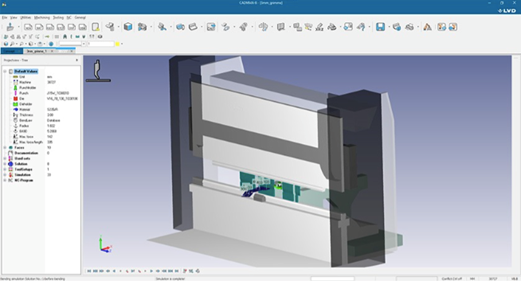

Algorithms encompass a broad range of computational methods designed to enable machines to perform tasks that typically require human intelligence. The AI algorithms, such as machine learning (ML) and deep learning (DL), are used to optimize metal fabrication processes by applying them to historical data and real-time data to achieve process optimization.

AI can analyze large volumes of data from sensors, equipment and production lines to optimize efficiency, improve quality and reduce downtime. By using algorithms to identify patterns in data, AI can anticipate potential issues, suggest prompt improvements, and even autonomously adjust processes in real-time.

Machine Condition Control

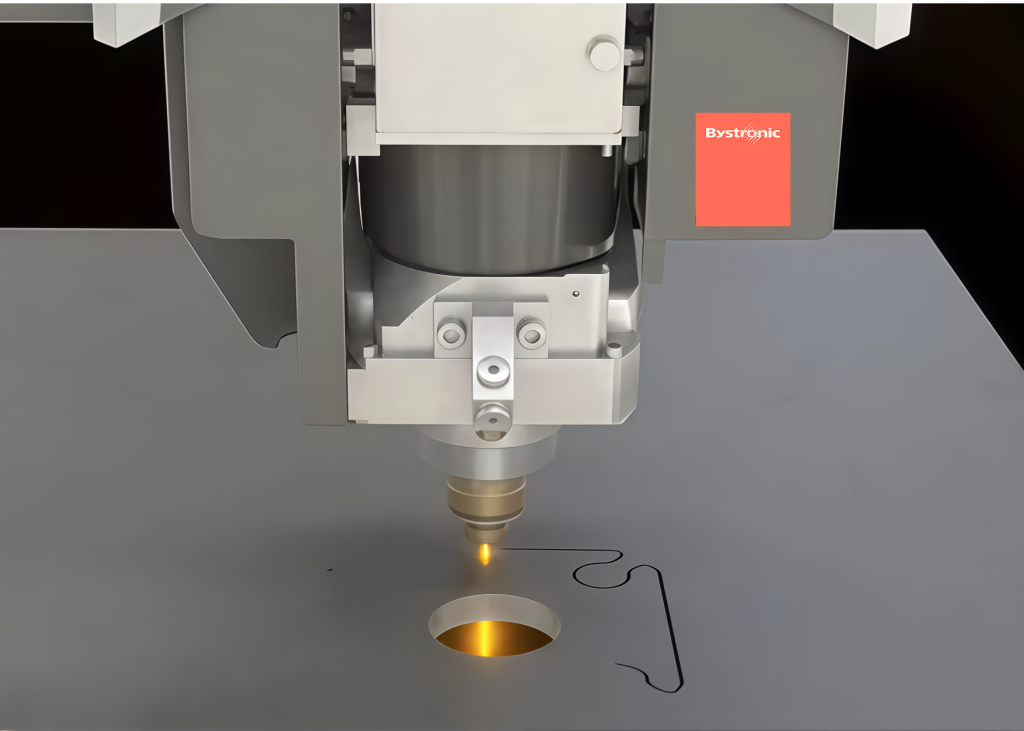

One of the most impactful applications of AI in manufacturing is machine controls. The integration of optical sensors and camera systems enables real-time monitoring of operational conditions, replacing the need for constant human oversight. Optical sensors can measure light intensity during laser cutting processes, ensuring that cutting conditions remain optimal and correcting issues on the fly. If a nozzle becomes misaligned or obstructed, the AI-powered system can detect this change and automatically stop the machine for verification and correcting the issue without operator intervention.

Similarly, machine learning (ML) has revolutionized the process of material parameter optimization. In traditional settings, operators would manually adjust cutting parameters when working with unfamiliar materials. To address this issue, Bystronic’s machine learning-driven “Parameter Wizards” is engineered to automate this process, quickly finding the optimal settings for new materials based on sample cuts. Furthermore, by evaluating results through an iterative process, the system fine-tunes cutting conditions, reducing downtime and ensuring high-quality cuts with minimal human input.

Quality Control

Quality control typically relies on human skills. AI-powered vision systems and data analysis optimize quality control by automating high-speed, real-time inspection, detecting defects, ensuring consistency, and reducing human error and cost. These systems analyze vast datasets to identify intricate patterns and predict potential issues, allowing for proactive both product and process controls.

AI-powered inspection systems allow for continuous monitoring of production lines, analyzing images captured by high-resolution cameras to identify surface anomalies, cracks, and other imperfections that might go unnoticed by human inspectors. The ability to analyze data instantly enables the detection and correction of defects as they occur, preventing defective products from escaping the production line to customers and reducing costly recalls and customer dissatisfaction. Unlike human inspectors, AI-powered inspection systems are not prone to fatigue or bias, leading to more accurate and consistent detection of defects.

TRUMPF, a leader in laser technology, has developed an AI solution that checks the quality of components, such as batteries for electric cars, immediately after laser welding, identifies possible defects and enables repairs in the laser welding station. “This enables users to reduce their manufacturing costs because the AI solution can replace other time-consuming quality inspections,” said Martin Stambke, the TRUMPF product manager responsible for AI quality inspection.

AI-driven Predictive Maintenance

AI-powered inspection systems are also able to process large volumes of data to identify trends and patterns within the production process. This allows for predictive maintenance, helping to anticipate potential machine failures or process deviations before they lead to machine problems. The AI-powered predictive maintenance offers numerous advantages that revolutionize practices across industries.

First, it significantly lowers maintenance costs by enabling proactive measures to address potential equipment failures before they occur. By analyzing data from sensors and monitoring systems, AI algorithms can detect early warning signs of malfunctions. This allows timely interventions to prevent equipment failures and reduces downtimes and the need for costly emergency repairs.

The AI-powered predictive maintenance is also able to predict component failures. For instance, in commercial trucking fleets, AI-powered predictive maintenance systems can analyze data, for example, from brake systems, to detect early warning signs of potential failures, such as abnormal temperatures, vibrations, or fluid leaks. Furthermore, AI-powered predictive maintenance contributes to extending the product’s lifecycle. By addressing issues promptly and preventing unnecessary strain on equipment, predictive maintenance reduces the frequency of replacements, machine downtime, and capital expenditures.

Optimized Material Handling

AI optimizes material handling in metal fabrication by using intelligent robots for precise and safe transport, data-driven route optimization for efficient movement of materials, real-time inventory tracking through IoT sensors, and intelligent sorting systems that reduce errors and speed up processes. By analyzing production data, AI also identifies inefficiencies and helps predict future material needs, leading to reduced waste, increased productivity, and a safer working environment for employees.

For automated transport of materials, AI-powered robots can handle, sort, and transport raw materials, finished parts, and scrap with high speed and precision, minimizing manual labor and reducing the risk of damage or mishandling. In addition, AI can train robots to perform the most dangerous and repetitive material handling tasks, improving worker safety, reducing the risk of injuries and improving the work environment.

Real-World Challenges

AI is truly a promising technology that the industry requires. However, AI-driven transformation in metal fabrication is still a work in progress. While the technology is impressive, applying it in a real-world shop environment is complex and requires more time, rich data and fine-tuning. Most importantly, AI needs accurate data as the computing concept states, “Garbage In, Garbage Out (GIGO)”. If the data is flawed, the AI’s recommendations will be equally flawed.

Will AI replace human workers on the shop floor? Don’t worry. Many experts believe AI will not replace human jobs but create new jobs instead. We believe that while technology keeps changing, humans are sustainable.

Article by: MEGA Tech