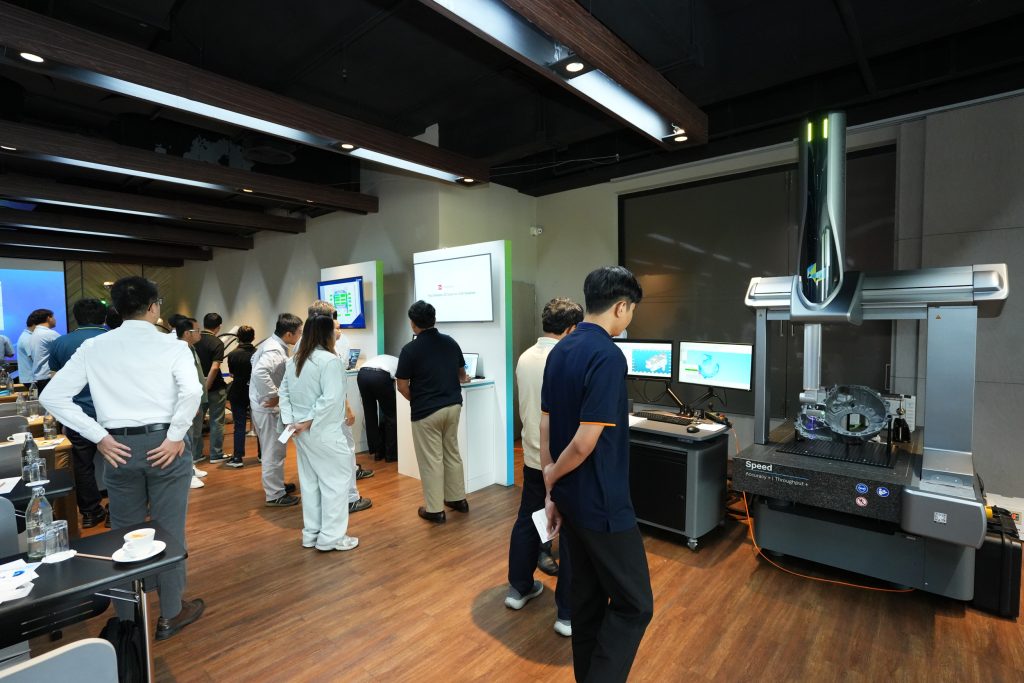

In an era where precision and efficiency define the success of modern manufacturing, the “Thailand Automation Seminar” — jointly organized by Hexagon Metrology (Thailand) Ltd. and TBTS (Thailand) Co., Ltd. — served as a significant platform reflecting the new direction of quality inspection technology. The seminar attracted a large number of professionals from the manufacturing sector and showcased the latest innovations in automation and metrology, complemented by live demonstrations conducted by experts. The event underscored the growing potential of Automation Metrology in driving Thai industries toward global standards.

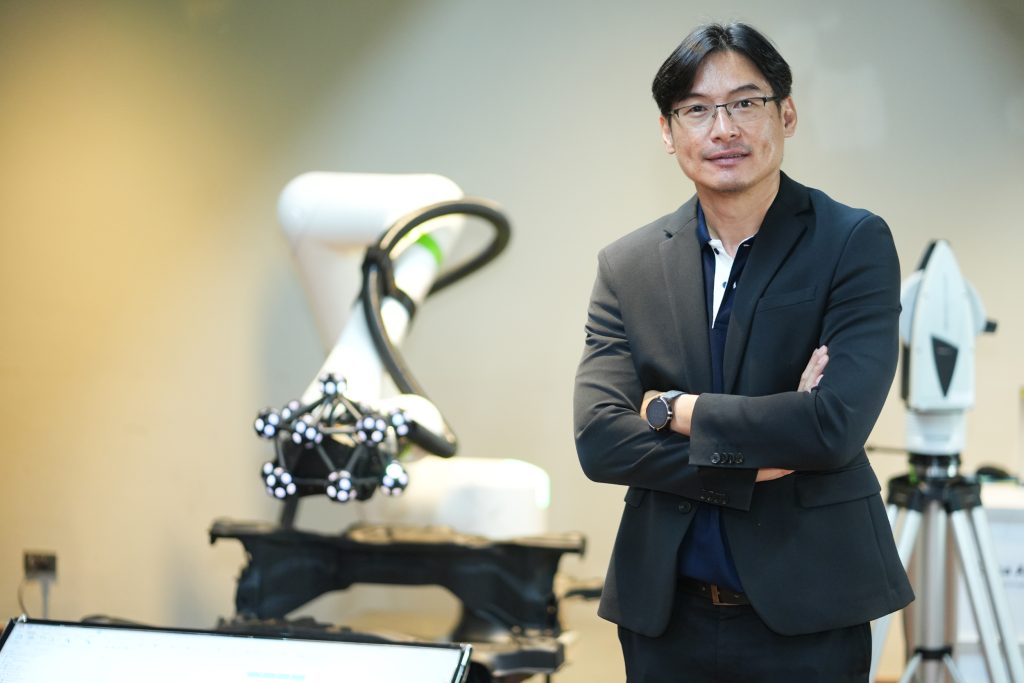

“We organized this seminar because we have witnessed continuous growth in Thailand’s automation market over the years,” said Mr. Kacha Panyaroj, Country Manager of Hexagon Metrology (Thailand) Ltd., as he began his discussion with MEGA Tech. “Our goal is to provide customers with a comprehensive overview of how Hexagon and TBTS technologies and solutions can effectively address today’s metrology challenges in the era of industrial automation.”

Participants had the opportunity to experience advanced technologies firsthand — from laser scanners integrated with robotic systems to various types of scanners widely used around the world — all brought together in one venue for direct comparison and testing. In addition, international experts shared practical insights and real-world applications of automation in metrology processes, enabling attendees to gain valuable knowledge that could be applied to enhance their own production systems.

Mr. Kacha concluded by emphasizing that “the selection of appropriate measurement processes depends greatly on product design. If a part requires high precision, the measuring instruments must be selected accordingly. However, we often find that some manufacturers, particularly in the automotive sector, still use measuring systems unsuited to the task — for example, applying CMMs to components that do not require such high accuracy, which leads to unnecessary time consumption.”

At this event, Hexagon and TBTS aimed to demonstrate that for applications not requiring extremely high accuracy, automation-integrated scanners can effectively replace traditional CMMs — cutting measurement time by more than half while still delivering sufficient precision for production requirements. The system has been proven in practice and offers a tangible solution for industrial operations.

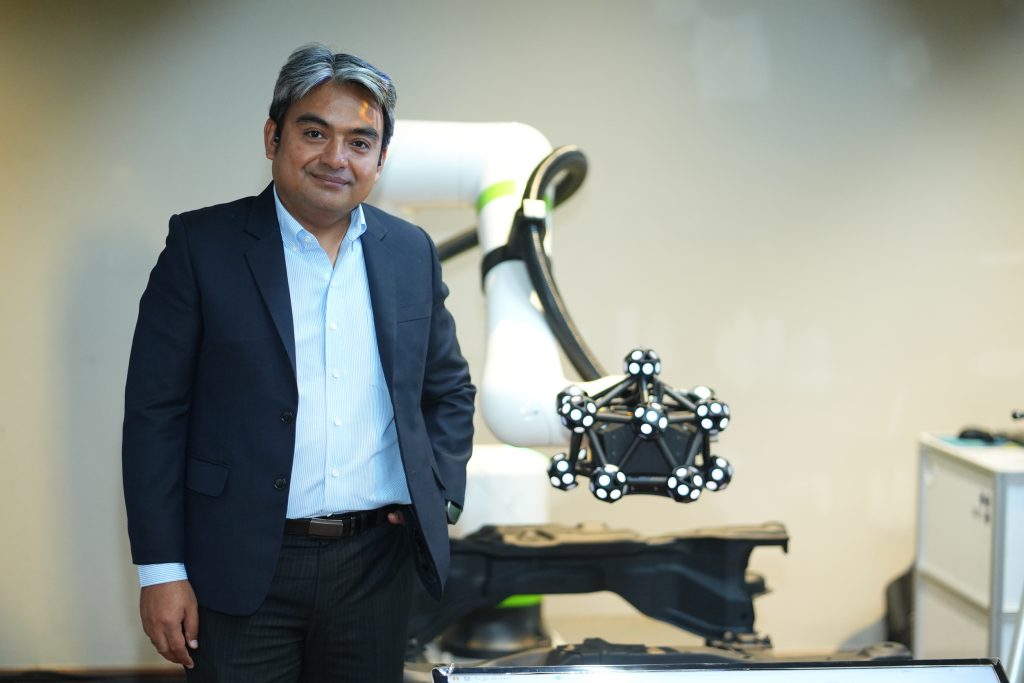

Following this, Mr. Ekachai Sripanyanuch, President of TBTS (Thailand) Co., Ltd., added:

“Our mission is to introduce automation systems that have been internationally validated for their performance and reliability — such as the Optium System, which has gained wide adoption in China, and the Laser Tracker, extensively utilized in Japan. Although these technologies are still emerging in Thailand, they represent a critical direction for manufacturers to consider in today’s highly competitive and quality-driven environment. As quality must go hand-in-hand with cost efficiency, automation plays a crucial role in reducing labor dependency, enhancing measurement accuracy, and elevating quality control standards to align with global demands. When automation systems achieve both precision and cost-effectiveness, manufacturers can significantly improve productivity in terms of both quality and efficiency. We believe this is truly ‘the answer for the future’ of Thailand’s manufacturing industry. TBTS will continue to support the industrial sector through advanced technologies that enhance production quality, strengthen competitiveness, and empower Thai manufacturers to move forward with confidence toward global standards of excellence.”

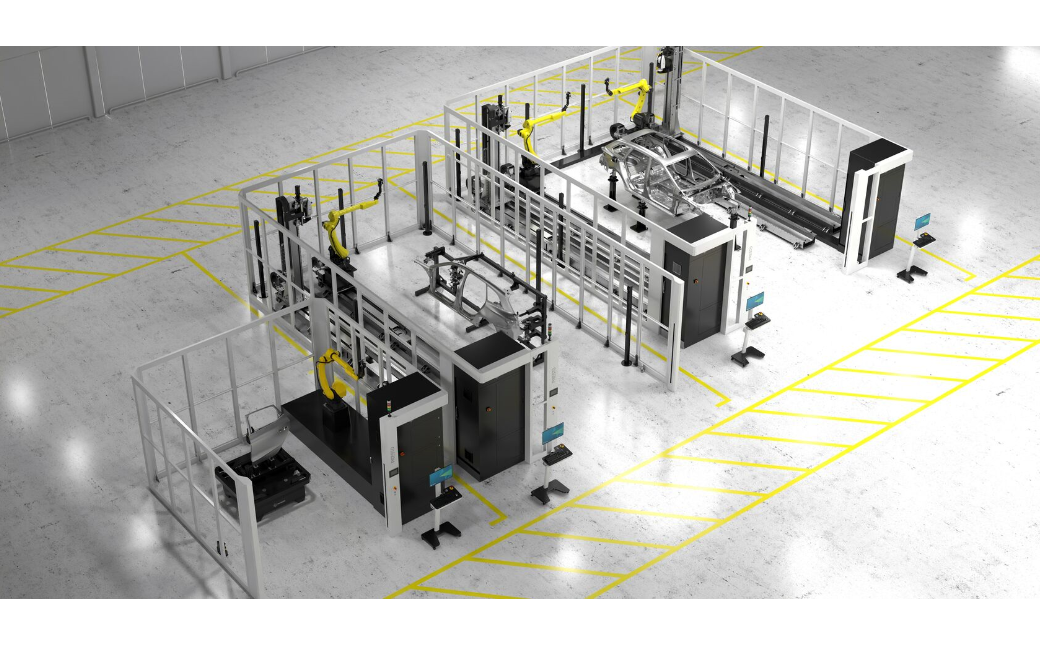

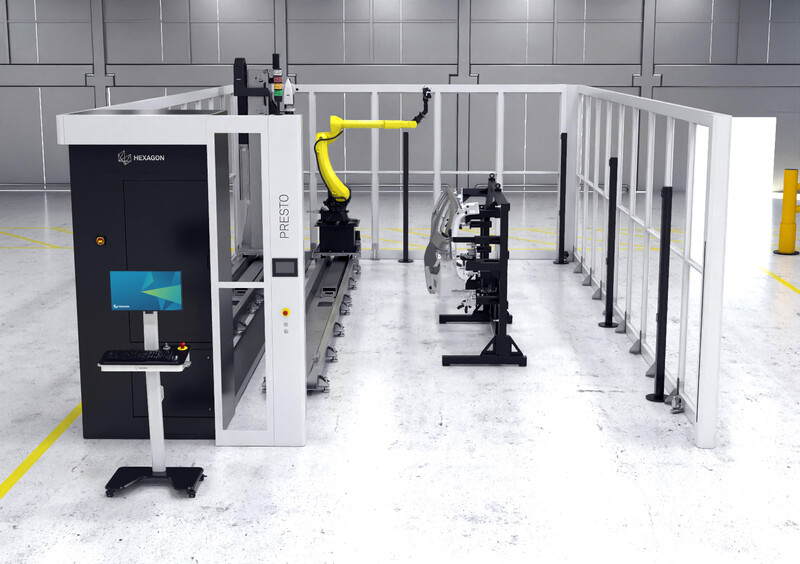

PRESTO Quality Stations Turn Bottlenecks into Gateways

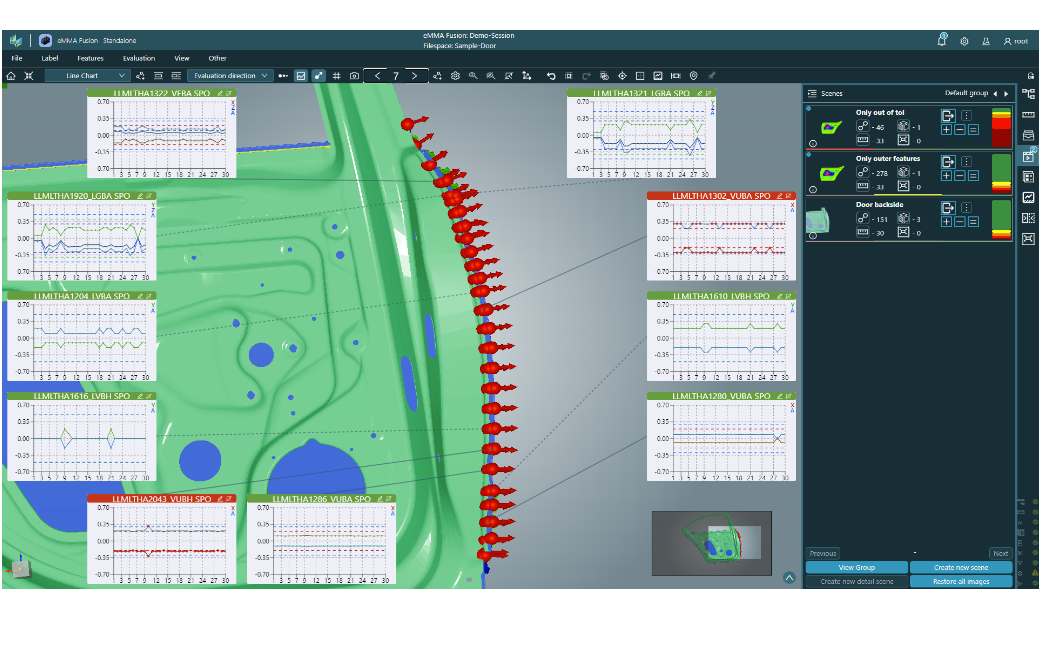

PRESTO Quality Stations are a suite of automated, robotic 3D measurement and quality inspection cells from Hexagon, designed to be flexible, scalable, and user-friendly for manufacturing environments like automotive and aerospace. The system combines advanced scanning and tracking technologies, offering high-resolution scanning and real-time dynamic tracking efficiency, especially in unstable conditions.

The system features a modular design that allows for scalability to meet various production needs, offering different configurations for different applications. PRESTO is designed to work with most third-party metrology software, allowing for easy integration into existing workflows without requiring users to learn new programming languages. Powerful robotic automation software, including digital twin simulation for offline programming, makes it possible for quality control specialists to create and deploy inspection programs quickly, even with limited experience.

PRESTO Quality Stations support the 5-step quality inspection process: prepare, plan, execute, analysis and report, helping transform the bottlenecks into gateways, meaning you can increase the throughput of your production. The product line includes PRESTO M, PRESTO L, and PRESTO XL.

The HYPERSCAN Series

The Hexagon HYPERSCAN series is a line of portable, handheld 3D laser scanners designed for high-speed, flexible, and accurate inspection of medium-to-large parts. The HYPERSCAN series uses an intelligent optical tracking system to track the scanner’s position in real time, so operators do not need to place targets on the part. The system continuously compensates for movement, part rotation, and vibration, allowing for accurate measurements even in unstable production conditions. With multi-mode scanning, users can switch between different scanning modes, including Standard, Fine, Line, Edge Detection, and Hole Flash, to optimize performance for various part surfaces, materials, and features. With a lightweight, ergonomic, and robust design, the scanners are easy to transport and use for extended periods in various locations, including the shop floor or in the field.

The HYPERSCAN series includes different models tailored for specific needs. The HYPERSCAN Ultra features a 5.5-meter tracking range and is optimized for great efficiency and accuracy when working with medium-sized parts or in confined spaces. The HYPERSCAN Super offers an extended 7-meter tracking range and faster scanning speeds, making it ideal for large-volume scanning tasks.

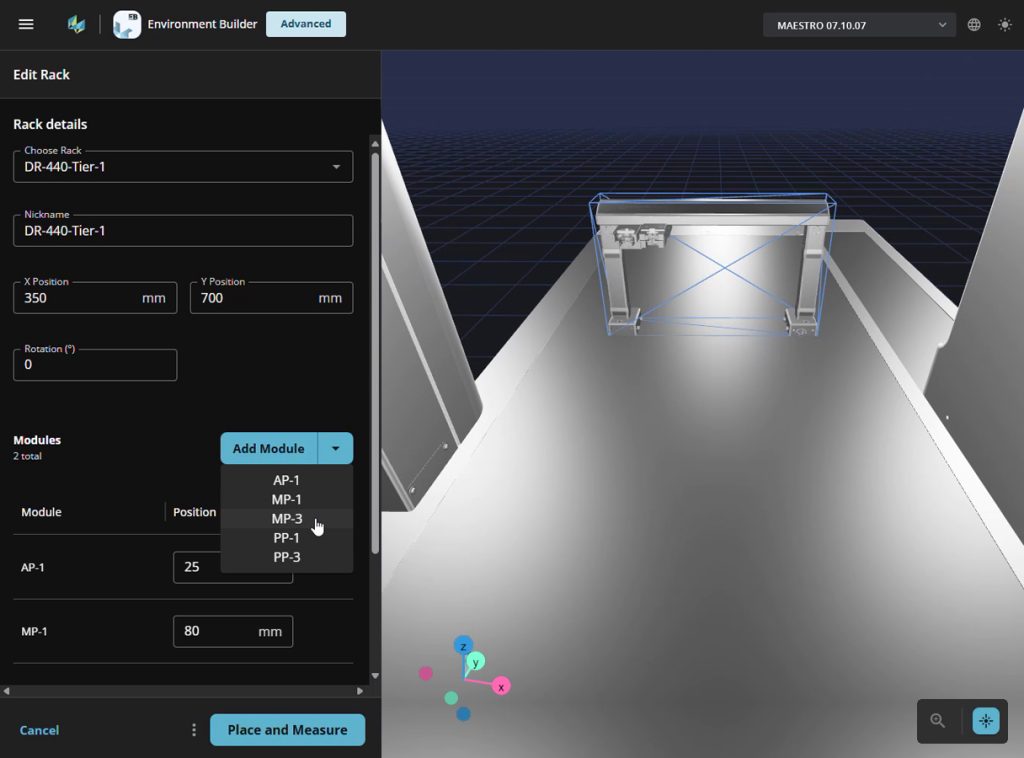

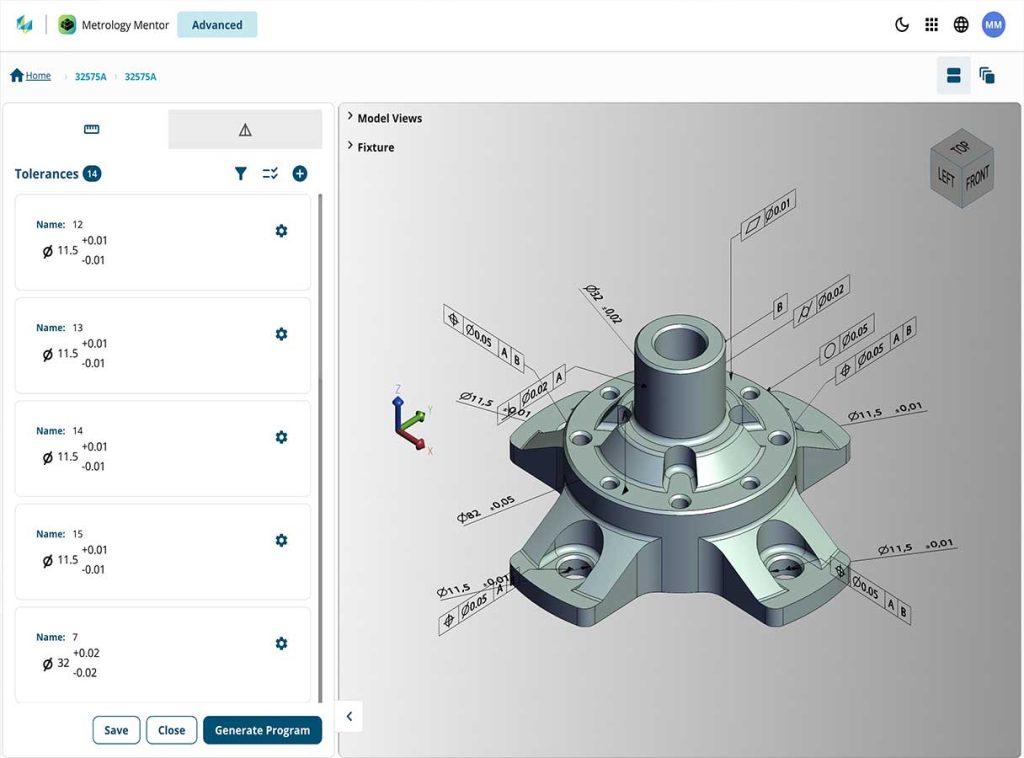

Hexagon’s MAESTRO CMMs

Hexagon’s MAESTRO is an all-digital, connected, and scalable next-generation Coordinate Measuring Machine (CMM) system built for modern manufacturing. The machine offers high-speed performance, simplified operation, intelligent software, and deep integration into Hexagon’s Nexus platform for real-time data sharing and smart decision-making that help manufacturer achieved Increased throughput and better decision making.

The Hexagon’s MAESTRO engineered as a complete digital system from hardware to software, incorporating digital sensors and a new controller for simplified setup and real-time data. It features industry-leading speed and precision, with synchronized axis movements and advanced sensors to increase measurement speed and capture points faster. The intuitive user interfaces and guided programming help reduce the learning curve for less experienced users.

Additionally, its modular hardware and software allow the system to be reconfigured or upgraded, providing flexibility and scalability to meet evolving production needs.

Article by: MEGA Tech & Hexagon Metrology (Thailand) Ltd.<< Click Here