The integration of 3D scanners serves as an essential first-step opportunity for manufacturers seeking to embrace automation. The 3D measuring solutions offer metrology-grade precision and unmatched flexibility, making them adaptable across a wide range of applicationsfor instance, design and development of products, quality control and insurance, reverse engineering, and direct utilization on product lines.

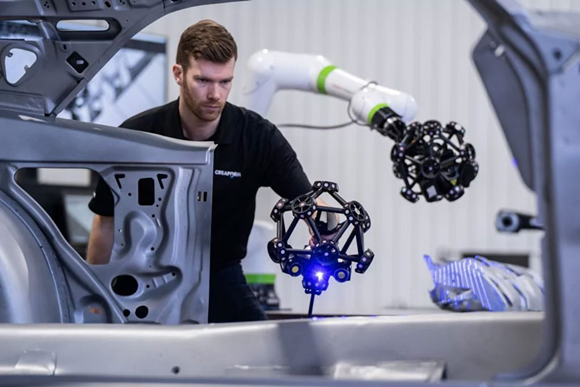

At the early stages of the manufacturing, 3D scanners provide simulation of design with high accuracy and resolution, forming a solid foundation for ensuring quality products when entering the production cycle. The 3D scanner can be used in evaluation and real-time quality inspection with high efficiency. In addition, it can be used in changing the functions for increased flexibility, from manual functioning requiring human intervention, to semi-automated process smoothly.

The flexibility and adaptability of 3D scanners allow manufacturers to begin their automation journey in a practical way, starting from small applications and gradually expanding the scope of use, without overhauling entire systems at once, especially for small and medium sized enterprise, where heavy consideration for returns is highly crucial. 3D scanning technology offers a cost-effective entry point into automation, eliminating the need for massive upfront investments in large, complex robotic systems during the early stages. By integrating this technology, SMEs can push their limits in automation facilitate business – all while maintaining financial stability. In addition, automation delivers significant benefits — such as enhanced precision and faster production — without the burden of high upfront costs.

The most compelling reason in integrating the use of 3D scanning technology regards its scalability – serving as a future-proof investment that supports continuous business growth. As businesses expand and demands evolve, the 3D scanning system can seamlessly adapt to accommodate the increased production volume or support new production lines with high efficiency.

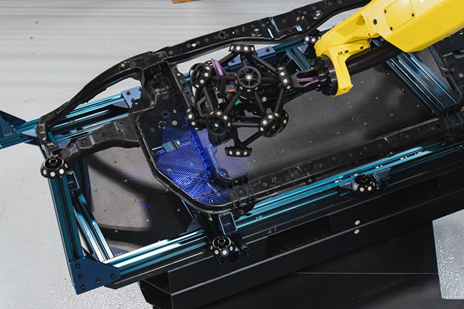

In conclusion, the 3D scanner is an equipment offering high flexibility and can be integrated in several automated solutions, for instance, the 3D scanner being used with robots or cobots to build automation in industry to for smooth and high working efficiency.

Key Considerations When Choosing a 3D Scanner:

When selecting a 3D scanner, it is important to consider certain key factors to ensure that the chosen solution can meet the needs of your business both in the present and future. These factors include:

1. Scalability

Opt for technology that can evolve with your needs — ideally starting with a handheld device that can later be integrated into fully automated systems. This allows you to begin small and scale up as your production requirements and budget grow.

2. Versatility

A robust 3D scanner should handle complex geometries and a wide range of materials without the need for extensive workpiece preparation. This flexibility ensures it can be applied across different scenarios, maximizing long-term value

3. Speed and Accuracy

Efficiency and precision are critical to maintaining product quality. Choose a scanner capable of rapidly capturing highly accurate data, ensuring quality control is both reliable and aligned with industry standards

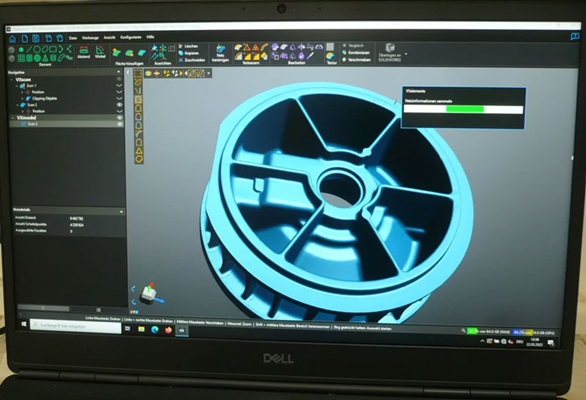

4. Software compatibility

Seamless integration with metrology, design, and simulation software is essential. This enables smooth data transfer across your workflows, supporting efficient analysis and decision-making throughout the production process

5. Supplier expertise

Select a supplier with proven expertise in both hardware and software, backed by strong customer support. This is particularly important for industries with complex production requirements.

Beyond these considerations, it’s valuable to ask whether the supplier has experience with automation projects using their scanners, and whether they provide tailored solutions for automated measurement tasks such as in-line quality control — including integration services to embed the technology directly into your production line.

Conclusion: 3D Scanners as the Gateway to Automation

For manufacturers navigating today’s competitive market, adopting a flexible and upgradable 3D scanning solution is a smart first step toward automation. The right 3D measurement technology not only strengthens product development and quality control but also boosts efficiency,

minimizes upfront costs, and builds a solid foundation for future growth. By strategically investing in 3D scanning, businesses can address current demands while preparing for scalable automation — ensuring long-term adaptability and success in the evolving era of smart manufacturing.

Article by: MEGA Tech & Ametek (Thailand) Co., Ltd. / Creaform. << Click Here