In today’s manufacturing world, where every micron defines quality, precision drilling has become a key process in producing high-value components such as molds, dies, and precision mechanical parts. The demand for tighter tolerances, smoother surfaces, and consistent accuracy drives the shift from general-purpose drilling tools toward specialized solid carbide solutions.

This article introduces the deep holes drilling process with H7 tolerance by using tools without internal coolant. Deep hole drilling refers to the process of creating holes whose depth exceeds five times their diameter — a critical operation in producing molds, hydraulic parts, precision machinery, and automotive components. Unlike standard drilling, deep hole applications demand exceptional control of straightness, roundness, surface finish, and chip evacuation throughout the entire depth.

One such innovation is the Crea borer, a specially engineered solution that redefines what’s possible in precision deep-hole machining.

The production of high-precision industrial components—such as molds, hydraulic parts, and precision machinery components—requires highly accurate drilling processes that ensure narrow tolerances, smooth surface finishes, and excellent dimensional consistency. These characteristics are critical factors that directly influence the performance, reliability, and service life of the finished parts.

Such demanding requirements have driven the development of specialized drilling tools designed to overcome the limitations of conventional drills, particularly in maintaining hole accuracy and quality. This article introduces an advanced deep-hole drilling technology capable of achieving H7 tolerance levels with exceptional precision without the need for an internal coolant system. In general, a “deep hole” refers to one with a depth greater than five times its diameter, where precise control of roundness, surface finish, straightness, and chip evacuation throughout the drilling depth is essential to produce components that meet the highest industrial quality standards.

Crea borer innovation

Crea borer was developed through collaboration between Nishiken Inc., a machine tool manufacturer in Hiroshima, and Goal Co., Ltd., a lock manufacturer in Osaka. This innovative drill can create holes up to 30 times the diameter.

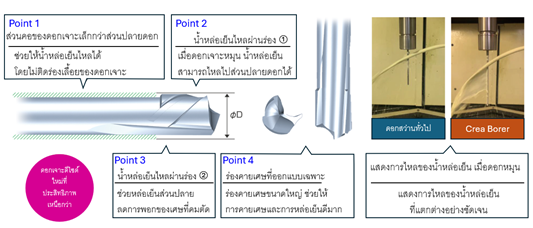

Crea borer stands out through its completely unique geometry:

unlike any conventional drill. It features a single cutting edge combined with two specially engineered coolant grooves positioned along the guide margin. These grooves work in harmony to cool the cutting edge efficiently while maintaining smooth chip evacuation. During rotation, the flute structure functions like a miniature coolant circulation pump, drawing fluid from the outside into the hole. This continuous flow carries heat away from the cutting zone together with the chips, allowing the Crea borer to achieve precise deep-hole drilling without the need for internal coolant supply. Another distinctive element is its underneck shape design, where only the outer diameter of the tip contacts the hole wall. This feature reduces friction, stabilizes tool guidance, and minimizes the risk of chip packing — one of the most common causes of tool failure in deep drilling.

Figure. 1

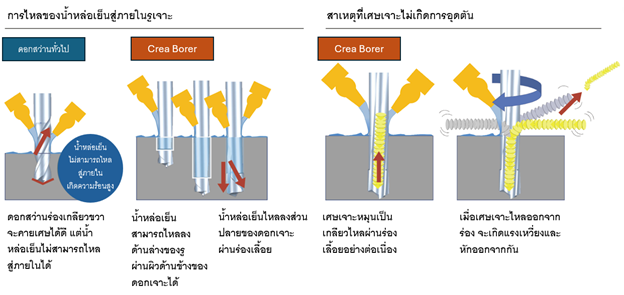

In traditional drills, as shown in the figure2, the chips are lifted and expelled due to the spiral twist of the flute. However, the coolant also tends to be expelled along with the chips, leaving the cutting edge almost without lubrication. This lack of coolant leads to heat buildup, causing significant damage to the tool edge. Crea borer features an under-neck structure, as previously explained, which is unaffected by the flute twist. Coolant enters through the gap, and as the hole depth increases, coolant pools in the area and is constantly supplied to the tip through two pump grooves, ensuring cooling and lubrication. This system is known as side-through cooling, as the coolant enters from the side of the hole.

Figure. 2

Moreover, the Crea borer produces uniform, curly chips that are automatically broken by centrifugal force once they reach a certain length, determined by spindle speed. This intelligent chip control prevents entanglement, protects the workpiece surface, and ensures continuous, stable drilling even in challenging deep-hole operations.

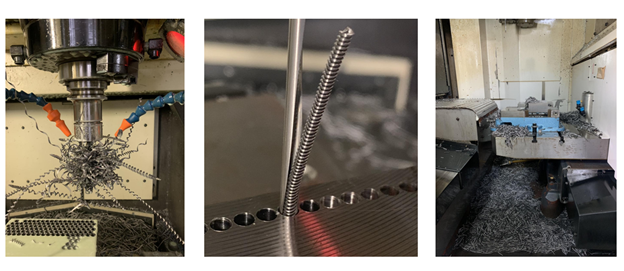

Figure. 3

To further validate the real machining performance of the Crea borer compared with conventional drilling methods, a controlled test was designed to quantify its accuracy and machining quality. The objective is to evaluate how effectively the Crea borer can produce deep holes with high geometric precision — specifically focusing on hole surface roughness, straightness and roundness — under standard shop conditions without internal coolant. For reference, the benchmark process will use a traditional combination of HSS drilling followed by carbide reaming, which represents the most common approach for achieving H7 tolerance holes in general machining.

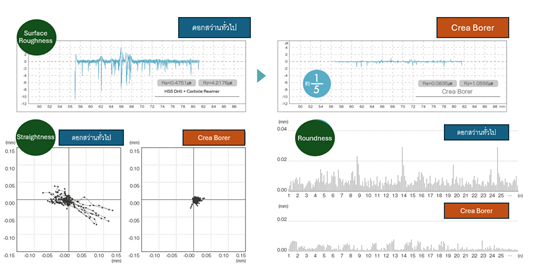

Here is the result from the testing.

- Surface roughness

- HSS drill + Carbide reamer Result: Ra = 0.4751 µm , Rz = 4.2178 µm

- Crea borer Result: Ra = 0.0835 µm , Rz = 1.0556 µm

- Straightness

- HSS drill + Carbide reamer Result: Deviation ranged from –0.10 mm to +0.12 mm, showing a noticeable scatter of hole positions and slight bending along the depth.

- Crea borer Result: Deviation contained within only ±0.01 mm, forming a tight cluster near the center. This result confirms that Crea borer maintains excellent hole alignment throughout the drilling depth, even without internal coolant, ensuring consistent accuracy in high-precision applications.

- Roundness

- HSS drill + Carbide reamer Result: The measured roundness deviation was approximately 0.010 – 0.015 mm, indicating a slightly oval hole shape caused by tool runout and vibration during the reaming process. Such irregularity can affect hole fit and dimensional stability, especially in high-precision assemblies.

- Crea borer Result: the roundness value improved dramatically to within 0.002–0.004 mm, showing nearly perfect circularity. This demonstrates how the tool’s single-edge design and stable chip evacuation mechanism suppress tool deflection and maintain accurate geometry throughout the drilling depth.

Overall, Crea borer delivers superior hole surface roughness , straightness and roundness consistency, enabling users to achieve reamer-quality finishes in a single drilling operation.

Figure. 4

If you are looking to achieve high-precision deep-hole drilling with greater simplicity and efficiency, the Crea borer offers a proven solution that eliminates the need for internal coolant while maintaining exceptional straightness, roundness, and surface quality. Whether you aim to improve hole accuracy, reduce tool change time, or enhance productivity on existing machines, Crea Borer can transform your drilling process.

Article by: MEGATech & Factory Max Co., Ltd. << Click Here