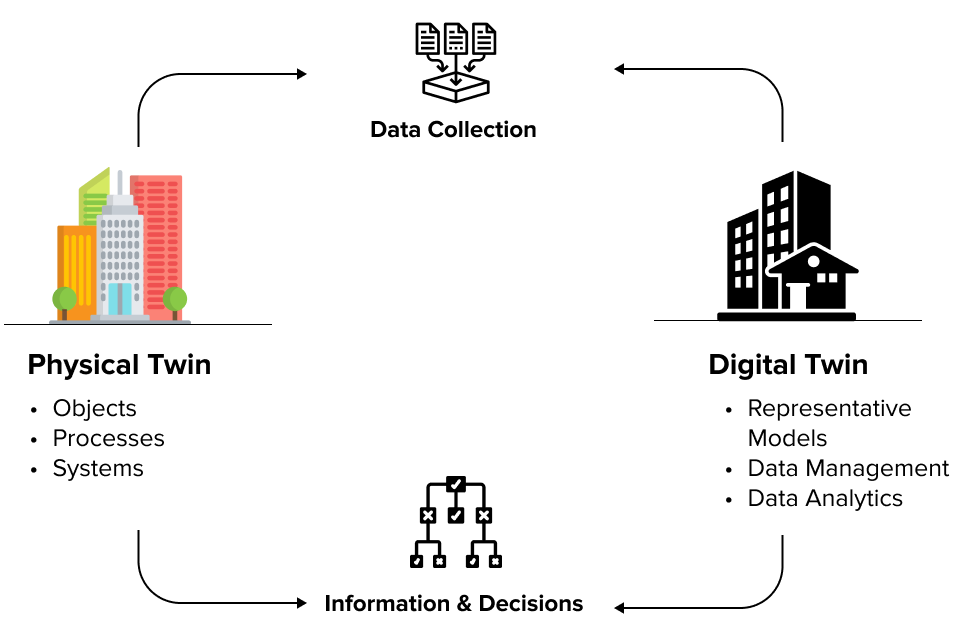

Supply chains are facing major challenges due to increased complexity, the COVID-19 pandemic, and intense competition. A potential solution to boost revenue and improve resilience is the use of AI-powered digital twins. These digital twins are virtual models of real-world objects, systems, or processes that allow for simulating different scenarios and predicting outcomes. By using real-time data, they provide valuable insights. Many organizations are already leveraging digital twins to optimize their operations, plan for various possibilities, and make better decisions. Market research suggests significant growth for the digital twin market, with annual increases of 30-40% expected over the next few years, reaching a value of $125 billion to $150 billion by 2032, according to McKinsey.

Source: 10 use cases and benefits of adopting digital twins in retail, Appinventiv

To illustrate how a self-healing supply chain functions, consider this example: a retailer uses digital twins to establish dynamic safety stock levels for each product (SKU) at every fulfillment center. These levels automatically adjust based on local and seasonal demand. This detailed optimization extends beyond just inventory management to encompass every aspect of the supply chain, from purchasing and product design to manufacturing and demand forecasting. For instance, the retailer’s detailed production planning can be coordinated with downstream transportation and inventory placement decisions. This dynamic planning might reveal, for example, a high-demand item with cross-selling potential where increased manufacturing costs are balanced by lower overall logistics costs due to combined shipping and improved customer conversion rates. This type of complex predictive modeling is a strength of digital twins. Typical outcomes in such situations include up to a 20% improvement in meeting customer expectations, a 10% reduction in labor costs, and a 5% increase in revenue.

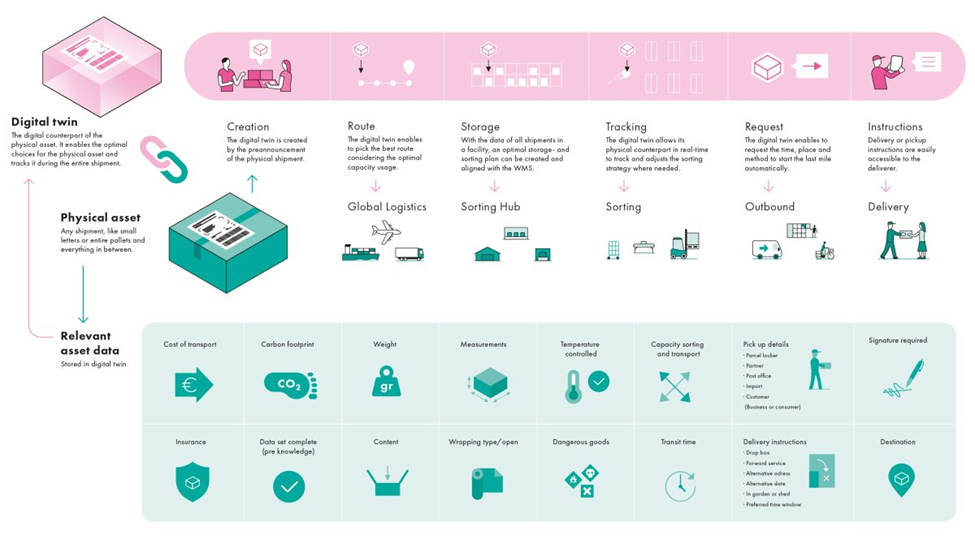

Modern supply chain management (SCM) software, encompassing tools like advanced planning and scheduling (APS), warehouse management systems (WMS), and transportation management systems (TMS), has automated significant portions of the supply chain over the last ten years, greatly improving interactions between suppliers, buyers, and shippers. Digital twins can integrate with these existing SCM tools, acting as an innovative overlay. By doing so, they can refine the data used by SCM tools, generating predictive analytics to handle various potential situations. For instance, a global original equipment manufacturer (OEM) developed a digital twin to optimize the policies it used within its TMS platform for outbound logistics. This resulted in an 8% reduction in freight and damage costs.

Source: Forwarder Magazine

Supply chain organizations are using digital twins to improve both their long-term strategies and day-to-day operations. We’ve most often seen companies use them for inventory positioning and forecasting, managing the movement of goods within warehouses and factories, and assisting with production planning. However, these are just some examples of how digital twins are being used across the supply chain. Regardless of the specific application, the advantages are evident: they benefit both strategic planning and daily operations.

On a strategic level, digital twins can reduce the risk associated with long-term planning and broader digital transformations by simulating possible outcomes. This type of “what-if” predictive modeling allows companies to confidently assess the complete impact of their strategic plans. For example, a retailer used a detailed digital twin of its distribution network to analyze the effects of a new distribution center design. Previously, the company had used a top-down approach to determine the size and location of a potential new cross-dock. However, by using a digital twin to model all the potential limitations of that cross-dock placement, they discovered they could resize and relocate it onto 50% less real estate without sacrificing functionality.

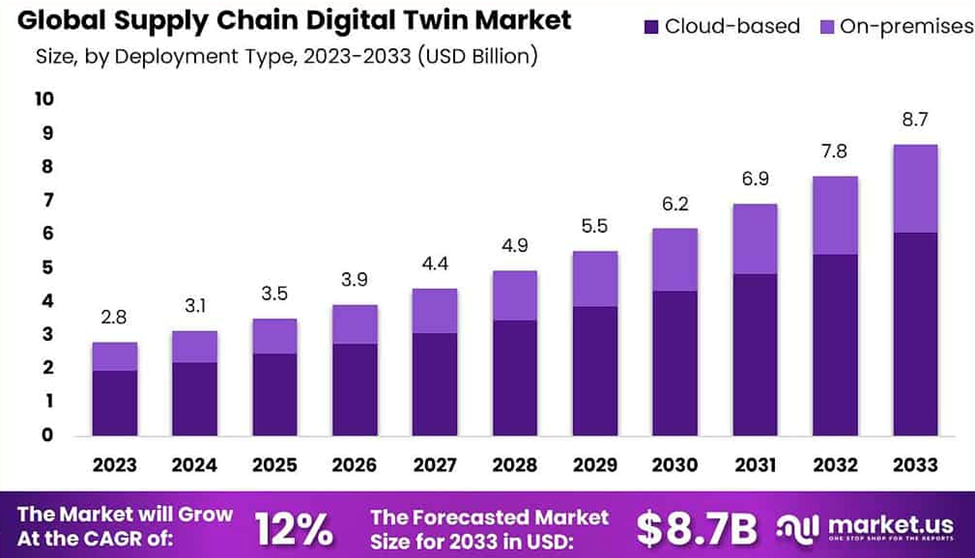

Supply Chain Digital Twin Market, Market.Us

On an operational level, beyond just influencing single strategic decisions, digital twins can serve as a central model, optimizing daily decision-making across various operations. Instead of using separate, unconnected predictive models, a digital twin can integrate multiple models for unified forecasting and decision-making. It dynamically weighs competing trade-offs across the supply chain to recommend detailed operational adjustments. For instance, the same retailer mentioned earlier used its digital twin not only to optimize the size and layout of its cross-dock within the distribution center but also to optimize daily inventory positioning. It forecasted weekly supply levels to balance cost, service quality, and sustainability. This resulted in a 10% improvement in regional distribution center utilization and a 5% reduction in fulfillment costs.

Article by: Asst. Prof. Suwan Juntiwasarakij, Ph.D., Senior Editor & MEGA Tech